Power generation using gas turbines increases over last year’s production by almost 5 percent but recorded a decrease in demand of 21 percent—making for an interesting year in the industry

COVID-19 sent a vast majority of Corporate America to work from home while facilities shut down across commercial and industrial sectors, all of which led to a drop in demand—albeit temporary—and we have yet to see the end of its effects in the coming years. However, Temp-Pro remains committed to supporting the future of gas turbine-powered energy generation with the most innovative and versatile temperature measurement devices.

The U.S. Government has been evaluating the short-term and long-term effects of a global pandemic for quite some time. Many scenarios have been considered where a decrease in demand triggers a slew of cause-and-effect sub-scenarios where lost income hinders the power producers’ ability to manage through their plans for 2020 and beyond.

Industrywise, the pandemic has also led to other challenges related to lockdown measures that caused gas turbine equipment maintenance to be deferred. Despite the drop in demand, the demand remains and if turbomachinery equipment isn’t maintained properly, it will eventually lead to an increase in failures. Temp-Pro advocates for maintaining temperature measurement devices as a precaution, even during these trying times, to prevent any challenges from becoming a threat to gas turbine operators and production schedules.

Although the recovery of the gas turbine market was evident, the COVID-19 situation has extended some of its hopeful markers beyond plan. Despite the upswing of value, the landscape continues to show an opportunity for new control system technologies, which increase the efficiency of the gas turbine operation. Add to this mix the political uncertainty and global emissions regulations and the industry will continue to evolve to manage through the challenges of a post-pandemic economy in the future.

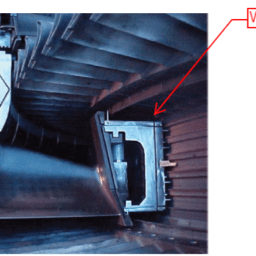

Gas turbine temperature sensors measure the temperature at different points in a gas turbine—from the exhaust temperature to the bearing temperature—supporting not only its safe operation but also ensuring that the output and performance remain within established operational parameters. To support the diversity of OEMs who produce gas turbines, Temp-Pro offers Thermocouples and PT100 RTD’s sensors in a variety of standard and nonstandard configurations.

Temp-Pro has been serving the Power Generation Industry for decades, with a strong reputation among gas turbine operators. Our leadership in the temperature measurement arena has supplied power plants with a variety of industrial thermometers and components such as sensors for Liquefied Natural Gas (LNG), Cool Down RTD Sensors, Multi-Spot or Average Tank Thermometers, Heat Tracing, Piping Systems, Pipe Clamp Sensors, Refining and Processing, Exploration and Extraction, and Flare Stacks.

Our gas turbine temperature sensors are constructed from mineral-insulated cable, which is fireproof, waterproof and extra-strength—all of which allow the sensor to operate in extremely high temperatures found in gas turbine equipment during peak operation. Depending on your specific needs or application, Temp-Pro’s industrial thermometers and components can be supplied in various grades of stainless steel and exotic alloys.

It should be noted that there are positive signs that will lead the Gas Turbine Industry to opportunity. Case in point, new technologies are pointing to the opportunity to upgrade to a large gas turbine unit for a lower cost than two smaller units that produce the same amount of output. With this in mind, Temp-Pro works with both OEMs and secondary gas turbine markets to deliver peace of mind to their operators, regardless of how their gas turbines are being used to meet energy demand.

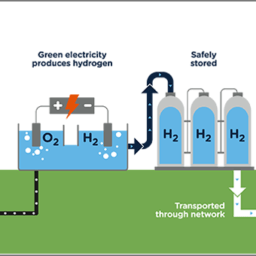

A decrease in demand leads to a drop in oil prices, as it has been noted in 2020 across the globe. Fossil fuel demand drops have a direct effect in Renewable Energy sources since the economic slowdown becomes a limiting force on the adoption of green fuels. Under the threat of an economic recession, the global energy market must weigh the effects of COVID-19 and how it plans to manage through until a full recovery.

Temp-Pro will remain a constant through the pandemic and beyond, offering our expertise and knowledge of industrial temperature measurement and devices. Contact us today at 1-800-991-9093 to explore OEM or maintenance needs for your industrial thermometers.