Direct Reduction Iron Ore Silos are critical components of the steel manufacturing process. These silos are used to store iron ore pellets, which are then fed into a furnace for processing. To ensure the quality of the pellets and maintain the integrity of the silos, accurate temperature measurement is vital. This is where Temp-Pro’s Type-K, Multipoint Wire Rope Thermocouples with Redundant Junctions come in.

Designed for Enhanced Performance:

• Multilevel sensors (50+ feet)

• Extended service life

• Reduction of replacement costs

• Reduction of down time

• Operating with greater degree of safety

Accurate Temperature Measurement: Ensuring Quality and Integrity

At Temp-Pro, we offer Wire Rope Thermocouples with multilevel sensors ranging 50 feet plus. This particular thermocouple has 4 junctions: 18 ft, 36 ft, 54 ft and 72 ft. These thermocouples are designed to provide accurate temperature readings at multiple points within the silo, ensuring that the temperature is consistent throughout the entire silo. The redundant junctions ensure that if one junction fails, the other junctions will continue to provide accurate readings, ensuring the safety and reliability of your process.

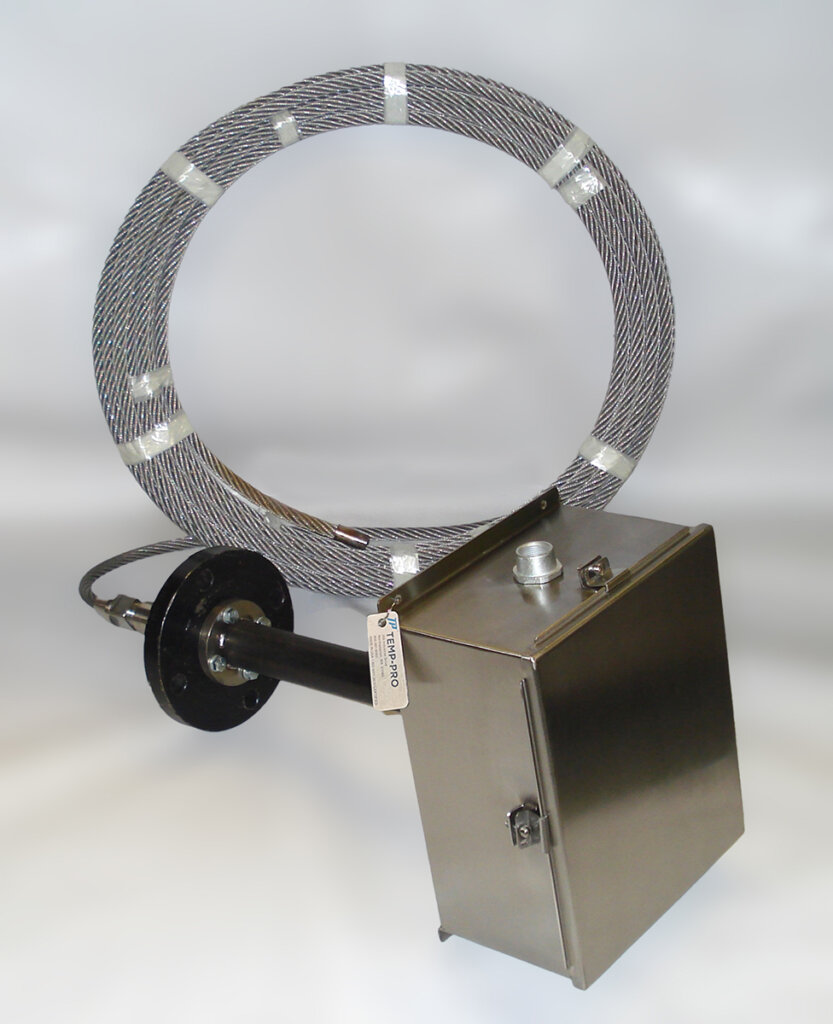

Multipoint assemblies are generally housed within a custom flanged well or pipe protection tube able to withstand the temperatures, pressures and corrosives within the vessel. Junction boxes of sheet steel, stainless, cast iron or aluminum (epoxy-coated if necessary) for general purpose, weatherproof or explosion-proof environments are either local or remote mounted. Any type of intermediate hardware can be supplied to interface the box with the well/sensor assembly.

Special designs include “miniatures” or small diameter units holding many probes with lengths over 100 feet. We also manufacture wells with the cold end sealed against possible intrusion of process into enclosure. Our open-ended guide tube assemblies permit the extension of the sensor directly into process per your specifications.

Key benefits of using Temp-Pro’s Type-K, Multipoint Thermocouples include:

Accurate temperature readings: Multipoint thermocouples provide accurate temperature readings at multiple points within the silo, ensuring that the temperature is consistent throughout the entire silo.

Improved process control: By providing accurate temperature readings, multipoint thermocouples help improve process control, which can lead to increased efficiency and reduced costs.

Increased safety and reliability: Redundant junctions ensure that if one junction fails, the other junctions will continue to provide accurate readings, ensuring the safety and reliability of your process.

Type-K thermocouples are one of the most commonly used thermocouples in industrial applications. They are made up of Chromel (90% nickel and 10% chromium) and Alumel (95% nickel, 2% manganese, 2% aluminum, and 1% silicon).

Key Takeaways

Key Takeaways

• Wire Rope Thermocouples are essential for Direct Reduction Iron Ore Silos

• They provide accurate and consistent temperature readings and increase safety and reliability

• Type K Thermocouples which are composed of Chromel and Alumel are common and reliable

Maintain Temperature and Ensure Quality with Temp-Pro’s Wire Rope Thermocouples

Wire Rope Thermocouples are essential for maintaining the temperature of iron ore pellets in silos. At Temp-Pro, we offer top-quality thermocouples that are designed to provide accurate and consistent temperature readings, ensuring the quality of your product and the safety of your process. Contact us today to learn more about our thermocouples and how they can benefit your business.