Temperature measurement is an essential parameter in various industries, including chemical processing, power plants, food processing, and pharmaceuticals. To measure temperature accurately, RTD temperature sensors are commonly used in these industries. The RTD, which stands for resistance temperature detector, is a type of temperature sensor that utilizes the change in resistance of a metal wire or element due to the change in temperature. This article will discuss RTD temperature sensors, their types, and applications, and how they differ from other temperature sensors.

An Introductory Overview of RTD Temperature Sensing

RTD temperature sensors are devices that measure temperature. They operate on the principle of the resistance of a metal changing with temperature. The sensor element is usually composed of platinum, nickel, or copper. The resistance change is linearly proportional to the change in temperature, making RTD sensors more accurate than other temperature sensors, such as thermocouples or thermistors.

The Basic Scientific Principles Behind RTDs

The RTD is a passive resistive device that measures temperature. It works by measuring the change in resistance of a metal wire or element due to the change in temperature. A Wheatstone bridge circuit usually measures the RTD’s resistance, which balances the unknown resistance with a known resistance. The Wheatstone bridge circuit has four resistors, including the RTD. When the temperature changes, the resistance of the RTD changes, causing an imbalance in the circuit. The change in resistance is then measured and converted into a temperature reading.

How RTD Sensors Adhere to Standardized Tolerances

RTD sensors come with different tolerance classes, which determine their accuracy. The most common tolerance classes are Class A, Class B, and Class C. Class A RTDs have the highest accuracy and are commonly used in laboratory applications, where accuracy is critical. Class B RTDs have a lower accuracy than Class A RTDs but are still suitable for most industrial applications. Class C RTDs have the lowest accuracy and are used in applications in which accuracy is not critical.

Exploring the Various Element Types in RTDs

RTDs come in various types of metals, each with its unique characteristics. The most commonly used RTD element types are:

RTDs come in various types of metals, each with its unique characteristics. The most commonly used RTD element types are:

Platinum RTD (Pt RTD): Platinum RTDs are the most popular type of RTD and are widely used in many industrial applications. They have excellent stability, accuracy, and linearity over a wide range of temperatures. Platinum RTDs are available in two resistance values: Pt100 and Pt1000.

Nickel RTD: Nickel RTDs are less expensive than platinum RTDs and are commonly used in applications when cost is a primary concern. They have a smaller temperature range and lower accuracy than platinum RTDs.

Copper RTD: Copper RTDs are the least expensive type of RTD and are commonly used in HVAC applications. They have a limited temperature range and lower accuracy than platinum RTDs.

Delving into the Precise Accuracy Levels of RTDs

RTD sensors are known for their high accuracy and linearity over a wide temperature range. The accuracy of an RTD sensor is determined by its tolerance class and the quality of the manufacturing process. Platinum RTDs are the most accurate type of RTD, with Class A RTDs having an accuracy of ±0.15°C at 0°C. Nickel and copper RTDs have a lower accuracy than platinum RTDs, with Class A RTDs having an accuracy of ±0.6°C at 0°C.

Understanding the Different RTD Connection Methods

RTDs can be connected in two-, three-, or four-wire configurations. Each configuration has its own advantages and disadvantages.

Two-wire configuration: Two-wire RTD connections are the simplest and most economical way to connect an RTD sensor. However, they are also the least accurate because the resistance of the lead wires can interfere with the measurement. Three-wire RTD connections are more accurate than two-wire connections because they eliminate the lead wire resistance. The three-wire configuration works by using two wires to connect the RTD to the measuring instrument and a third wire to compensate for the lead wire resistance. This compensation wire is connected to the two RTD leads at the measuring instrument, and it is connected to one RTD lead at the sensor end.

Four-wire configuration: Four-wire RTD connections are the most accurate because they eliminate lead wire resistance completely. The four-wire configuration works by connecting the two RTD leads to one set of wires and the other two wires to the measuring instrument. The two wires connected to the RTD leads measure the RTD resistance, and the other two wires provide excitation voltage to the RTD.

Lead Wire Effects: One of the main issues with RTD sensors is the effect of lead wire resistance on accuracy. The lead wire resistance can cause measurement errors, especially in two-wire configurations. To minimize the lead wire effect, manufacturers often use high-quality materials for the lead wires and keep the wire length as short as possible. Another way to minimize the lead wire effect is to use three or four-wire configurations.

The Core Concept of Resistance-Based Temperature Detection

The resistance temperature detector (RTD) is a commonly used type of temperature sensor. It measures temperature by sensing the change in resistance of a metal wire or element due to temperature changes. This resistance change is linearly proportional to the temperature change, making RTDs highly accurate and reliable sensors.

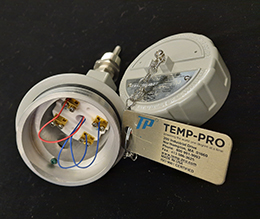

How RTD Probes and Their Assemblies are Structured

RTD probes and assemblies protect the RTD sensor from the environment and provide a secure mounting point. RTD probes come in various shapes and sizes, depending on the application. Common probe types include straight probes, spring-loaded probes, and surface probes. RTD assemblies protect the RTD sensor from harsh environments, such as high-pressure or corrosive applications. The assembly typically includes a protective sheath made of stainless steel or other high-temperature materials and a terminal head for wiring.

A Deep Dive into Individual RTD Sensor Parts

RTD sensor elements are the heart of the RTD sensor. They are made of a metal wire or element that changes resistance with temperature changes. The most common RTD element materials are platinum, nickel, and copper. Platinum is the most commonly used material because of its excellent stability, accuracy, and linearity over a wide temperature range.

Real-world Applications Where RTD Sensors Shine

RTD sensors are used in various industrial applications, including chemical processing, power plants, food processing, and pharmaceuticals. They are also used in laboratory applications, where accuracy is critical. RTD sensors are ideal for applications that require high accuracy and linearity over a wide temperature range. Some of the most common applications of RTD sensors include:

HVAC systems: RTD sensors measure temperature in HVAC systems, such as air handling units, boilers, and chillers.

Process control: RTD sensors measure temperature in chemical processing, food processing, and pharmaceuticals.

Power generation: RTD sensors measure temperature in power generation equipment, such as turbines and generators.

Adhering to Globally Recognized RTD Sensor Standards

Various organizations provide standards for RTD sensors, including the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). These standards define the tolerance classes, lead wire configurations, and other specifications for RTD sensors. The most common RTD standards are IEC 60751 and ASTM E1137.

A Catalog of the Different RTD Sensor Variants Available

RTDs are available in various types, depending on the material used for the sensor element and the tolerance class. The most common RTD types are platinum, nickel, and copper RTDs. Platinum RTDs are the most commonly used type of RTD, followed by nickel and copper RTDs. RTDs are also available in different tolerance classes, with Class A and Class B being the most commonly used classes.

Analyzing the Specifics of 2-, 3-, and 4-Wire RTDs

The main difference between two-, three-, and four-wire RTD configurations is the number of wires used to connect the RTD to the measuring instrument. Two-wire configurations are the simplest and most economical way to connect an RTD sensor, but they are also the least accurate because the lead wire resistance can interfere with the measurement. Three-wire configurations are more accurate than two-wire configurations because they eliminate the lead wire resistance. Four-wire configurations are the most accurate because they eliminate lead wire resistance completely.

Differences and Similarities: Pt100 vs. Pt1000

Pt100 and Pt1000 are two common resistance values for platinum RTDs. The difference between them is the resistance value at 0°C. Pt100 has a resistance value of 100 ohms at 0°C, while Pt1000 has a resistance value of 1000 ohms at 0°C. Pt100 RTDs are more commonly used than Pt1000 RTDs because they are compatible with most standard measuring instruments. Pt1000 RTDs are less common but have some advantages, such as higher resolution and lower lead wire resistance.

Pitting RTD Sensors Against Thermocouples: A Comparative Study

RTDs and thermocouples are two common types of temperature sensors. The main difference between them is the principle of operation. RTDs measure temperature by sensing the change in resistance of a metal wire or element due to temperature changes, while thermocouples measure temperature by sensing the voltage generated by the junction of two dissimilar metals. RTDs have higher accuracy and linearity than thermocouples, making them ideal for applications that require high accuracy and stability over a wide temperature range. However, thermocouples have some advantages, such as higher temperature ranges and faster response times.

Drawing Distinctions Between RTDs and Thermistors

RTDs and thermistors are types of resistive temperature sensors. The main difference between them is the material used for the sensing element. RTDs use a metal wire or element, while thermistors use a ceramic or polymer material. RTDs have higher accuracy and linearity over a wide temperature range than thermistors. However, thermistors have some advantages, such as faster response times, higher sensitivity, and lower cost.

The Science of How RTD Sensors Operate

RTD (resistance temperature detector) sensors work by sensing the change in resistance of a metal wire or element due to temperature changes. This resistance change is linearly proportional to the temperature change, making RTD sensors highly accurate and reliable for temperature measurement. A Wheatstone bridge circuit typically measures the resistance in RTD sensors. The RTD is available in various configurations, including two-wire, three-wire, and four-wire. Overall, RTD sensors are widely used in various industrial applications for their accuracy, linearity, and stability over a wide temperature range.

Understanding the Unique Traits of RTDs vs. Thermocouples

The main difference between RTDs and thermocouples is the principle of operation. RTDs measure temperature by sensing the change in resistance of a metal wire or element due to temperature changes, while thermocouples measure temperature by sensing the voltage generated by the junction of two dissimilar metals. RTDs have higher accuracy and linearity than thermocouples, making them ideal for applications that require high accuracy and stability over a wide temperature range. However, thermocouples have some advantages, such as higher temperature ranges and faster response times.

RTD (resistance temperature detector) sensors work by sensing the change in resistance of a metal wire or element due to temperature changes. This resistance change is linearly proportional to the temperature change, making RTD sensors highly accurate and reliable for temperature measurement. A Wheatstone bridge circuit typically measures the resistance in RTD sensors i The RTD is available in various configurations, including two-wire, three-wire, and four-wire. Overall, RTD sensors are widely used in various industrial applications for their accuracy, linearity, and stability over a wide temperature range.

Highlighting the Beneficial Aspects of RTD Temperature Sensing

The main advantage of RTD (resistance temperature detector) sensors is their high accuracy and linearity over a wide temperature range. RTDs measure temperature by sensing the change in resistance of a metal wire or element due to temperature changes, and this change in resistance is linearly proportional to the temperature change. The linear relationship between resistance and temperature makes RTDs highly accurate and reliable for temperature measurement. Additionally, RTDs have excellent stability over time, making them suitable for long-term measurements. Overall, RTDs are the preferred temperature sensors for applications that require high accuracy and stability over a wide temperature range.

Summary

In conclusion, RTD temperature sensors are essential devices that measure temperature in various industrial applications. They are highly accurate and reliable sensors that operate on the principle of the change in resistance of a metal wire or element due to temperature changes. RTDs come in various element types, tolerance classes, and lead wire configurations, making them versatile sensors suitable for a wide range of applications. Platinum RTDs are the most commonly used type of RTD, followed by nickel and copper RTDs. RTDs are superior to other temperature sensors, such as thermocouples and thermistors, in terms of accuracy and linearity over a wide temperature range.

Here are a few more helpful resources from the Temp-Pro team:

Stator Temperature Sensors for All Industrial Applications

RTD vs Thermocouple Temperature Sensors