In 2020, the cement industry produced 90 million tons of Portland cement in America alone.

Cement plays a vital role in constructing the essential infrastructures such as housing, roads, schools, hospitals, dams and ports. Cement is a paramount building material in the world.

Manufacturing cement is not as simple, though. It requires a meticulous process that cement plant workers must follow. Cement temperature itself is one vital factor affecting the production process and quality. Thus, the need for thermocouples for cement.

Our cement temperature sensors ensure this complex process is stable. Read on to learn exactly how.

Cement Production Process

It’s vital to review the cement manufacturing process before anything else. Below is the step-by-step cement production process:

- Crushed limestone, together with clay, slate, slag, and other materials, reduce to a size of 75 mm or less.

- The particles enter a pre-heating process before moving into a rotary kiln, heating up to 1,370 C.

- The raw materials advance through the rotary kiln into the firing zone. These materials dry, and other components form a clinker with lumps at around 25 mm diameter.

- The heated clinker cools as it exits the kiln, and the heat returns to the pre-heater. This increases productivity, reduces cost and decreases the process’s environmental impact.

- Extra cement ingredients, like calcium sulfate, mixes with the powdered cool clinker.

- The final cement product is then ready for packaging and shipment.

Temperature Sensors Ensure Process Stability

Temperature control over the process is crucial to sustaining efficiency and quality. It also prolongs the rotary kiln’s lifespan.

Within the kiln, cement burning, and manufacturing temperature control are the burning zone, shell, and cooler.

In a cement factory, the rotary kiln is the most significant machinery. It’s a long metal tube that does most of the manufacturing process. It has a ceramic lining protecting the outside shell from the interior’s temperatures.

The kiln has a diameter of up to 4 meters and a length of up to 50 meters. It rotates three to five times each minute on average. The cement material moves downward the burning zone as it spins, heating up in the process.

For this structure, temperatures within the kiln can differ, making tracking more difficult.

Burning Zone

The burning zone, or the fire zone, sits at the bottom of the rotary kiln. The elements heat up from 1,300 C to 1,450 C to produce clinker.

Precise cement temperature measurement determines the product quality, sustainability practices, and kiln lifetime.

A cement kiln’s interior is a complex environment to take a measurement. The interior is hot dusty, and particles move, harming an improper measurement device.

A thermocouple is one of the most common temperature sensors for cement.

A data logger connects to the thermocouples to record the temperature at intervals. The predetermined intervals vary depending on the type of device.

There are many thermocouples to choose from depending on the cement production process. When selecting a cement thermocouple type, consider the firing temperature and environmental protection.

Kiln Shell

It’s crucial to keep an eye on the temperature of the kiln shell from the outside. One or two layers of refractory brickwork insulate the metal kiln shell from much heat.

The brickwork could collapse due to erosion or actual loss of bricks. It could damage the metal and put the kiln out of commission.

Detecting hot spots of damage can save money on maintenance and prevent shutdowns. Continuous inspection over the kiln allows for the early diagnosis of faults. It will allow for rectification before significant damage occurs.

A thermocouple for cement is one of the types of sensors used in manufacturing suitable for this. It measures the temperature of the kiln’s shell, allowing for maintenance.

Clinker Cooler

Clinker refers to the solid cement lumps that emerge from the rotary kiln. The hot clinker should move from the kiln to a grate cooler to chill with air blowers.

A conveyor belt takes the cooled clinker away into the powdering process or storage.

It’s critical to keep an eye on the clinker for any stray hot inclusions that could cause harm to the conveyor belt. If clinker fragments become too hot, they might cause significant difficulties. They can harm the conveyor belt, halting the entire manufacturing process.

Temperature Sensors Sustain Product or Ingredient Quality

Temperatures affect the curing process and strength of cement during production and placement.

Extreme heat fractures cement. Thus, many large projects use chilled water to control the temperature. It limits the risk of breaking and damages.

High temperatures during the pouring process can crack cement, compromising its durability. Moreover, hot temperatures reduce cement usability, making the process more difficult.

Different Types of Cement Need Specific Temperatures

Certain chemical and physical restrictions ensure consistency between cement-producing factories. A lot of standards and specifications establish these chemical limitations.

Construction documents specify the cement types. The cement’s desired performance or placement conditions are often the basis.

Some blended cement has unique performance characteristics. Air content, fineness, expansion, and strength are standard physical cement criteria. It also includes the heat of hydration and setting time.

The majority of these physical tests involve cement mortar or paste.

Temperature Sensor Saves Money

Saving money on operational costs in the cement business results from maintaining equipment. Maintaining equipment lowers the risk of unplanned shutdowns and improves preventative maintenance activities. The kiln shell, in particular, needs the most monitoring.

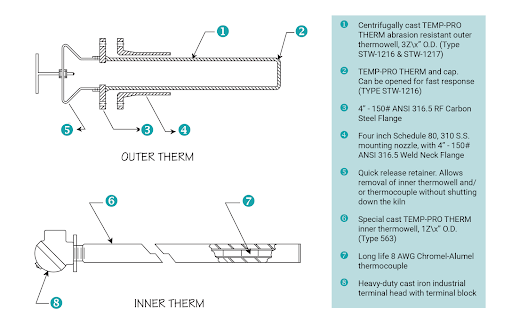

Temp-Pro Therm

Temp-Pro Therm is a feature Temp-Pro provides. It is an extremely rugged nickelchrome alloy with cobalt and tungsten added for stabilization and strengthening. The centrifugal casting of the outer thermowell assures removal of impurities, oxides, and gases from the alloy. Additionally, the purity and densification of the alloy molecules contribute to the high strength and abrasion resistance of the contact thermocouple. It is successfully used in petrochemical, smelting, refining, furnace, and heat treating applications.

Features provided by Temp-Pro Therm are:

- Superior Performance Up To 2300 degrees Fahrenheit.

- Double-Well Design with Quick Release Function for Inner Thermowell and Micro Thermocouple.

- Excellent Abrasion & Corrosion Resistance for use in Rotary Cement Kilns.

- Outstanding Corrosion Resistance in sulphorous, oxidizing, and reducing atmospheres.

Find the Best Concrete Temperature Sensors Today

Temperature measurement in cement production plays a vital role. Minor discrepancies could cause a significant change in the quality of the cement. Get the best temperature sensor in the market now!

Are you looking for the right type of cement temperature sensors but don’t know where to get them? Contact us and let us help find the best temperature sensor that fits your project.