For those who are unfamiliar with the concept of air-separation, an air-separation unit (ASU) separates atmospheric air into its primary components, typically nitrogen, oxygen, and sometimes argon, as well as other rare inert gasses.

With this in mind, let’s delve deeper into the crucial role of ASUs and the potential temperature applications in modern industries.

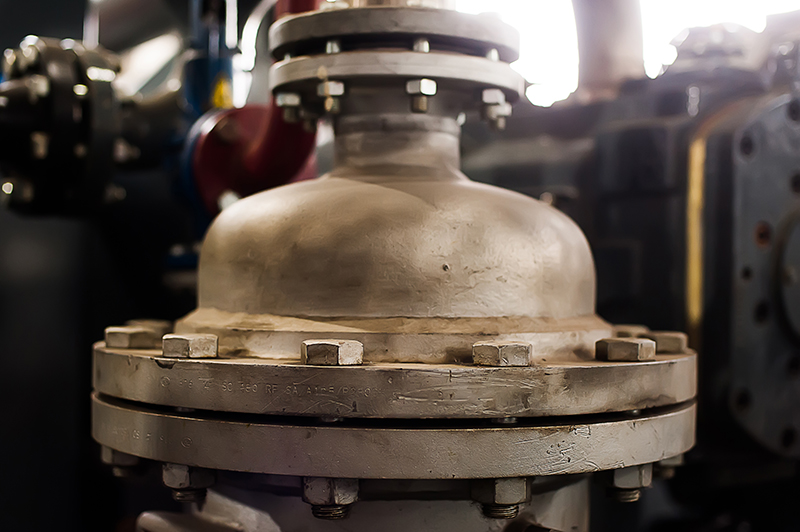

The plant comprises an assembly of equipment like distillation columns, heat exchangers, adsorbers, and supporting machinery for compression, expansion, and control of gasses and liquids.

What types of industries use ASUs?

You may be wondering which industries use ASUs? They are as follows:

- Chemicals

- Iron & steel

- Healthcare

- Food & beverages

- Paper & pulp

- Oil & gas

The type of industry and purpose of the units dictate how the ASUs are used.

ASUs provide important feedstock for several major manufacturing industries. For instance, argon is used in welding, oxygen is used in steel production, and nitrogen is used as an inert gas in food and metal processing. Moreover, there is a strong demand for air-separation plants in the healthcare, iron & steel, and chemical sectors, as there is an increasing need for high-purity gasses such as oxygen, argon, hydrogen, and helium.

Additionally, there is a surging demand for nitrogen gas within the food & beverage sector. This is because there is a growing emphasis on gas packaging, rapid refrigeration, and freezing technologies, which is fueling the demand for freezing with liquid nitrogen. Many industrial activities are shifting toward high-purity gasses, which is boosting innovation in the air-separation plant market.

The location of cryogenic air separation plants is also of note. Typically, air separation sites are located close to large tonnage customers such as steelworks, chemical works, petrochemical plants, oil refineries, and smelters so that the gas may be supplied directly to the customer by pipeline.

What are the types and uses of ASUs?

There are two primary technologies to separate the gasses in air: cryogenic distillation and non-cryogenic separation. Non-cryogenic methods are typically commercially used to separate a single component from atmospheric air. However, they are less energy efficient than cryogenic plants.

Cryogenic ASUs provide nitrogen or oxygen and often co-produce argon. High-purity oxygen, nitrogen, and argon, which are used for semiconductor device fabrication, require cryogenic distillation. The most common method for air separation is fractional distillation, which utilizes both thermocouples and resistance temperature detectors (RTDs) in the distillation and fractionation processes. Thermocouples and RTDs are the most common types of sensor used in distillation and refining. The only viable source of rare gasses such as neon, krypton, and xenon is the distillation of air using at least two distillation columns. Helium has to be recovered by advanced air-separation processes.

Non-cryogenic plants can use membrane separation, pressure swing adsorption or vacuum pressure swing adsorption.

Comparing and contrasting

Unlike cryogenic plants, which use the difference between the boiling points of nitrogen and oxygen to separate and purify gasses, non-cryogenic air-separation plants use differences in physical properties, such as molecular structure, size, or mass, to produce nitrogen and oxygen. Non-cryogenic processes are based on either selective adsorption or permeation through membranes.

Cryogenic air-separation processes are routinely used in medium to large-scale plants to produce nitrogen, oxygen, and argon as gasses or liquids. They are considered the preferred technology for producing very high-purity oxygen and nitrogen. This is because it is the most cost-effective technology for high-rate production plants. Thus, virtually all plants producing liquefied industrial gas products utilize cryogenic technology.

Sensors

Pipeline to inline temperature measurement devices include RTDs, Thermocouples and Thermowells. Thermocouples, for example, are versatile. They are small and can be used in harsh environments over an extremely wide temperature range. Thus, they are often the best choice for cryogenic and ultra-low-temperature processes.

Type T thermocouples are one of the best options since they are very stable at low temperatures. These thermocouples consist of a positive copper wire leg and a negative constantan alloy wire leg. This type of thermocouple is also a great choice because they can perform well and still provide a high level of accuracy in the presence of moisture without oxidizing.

Cryogenic distillation

Here are some common uses of thermocouples in air separation units:

Column temperature measurement: ASUs typically use distillation columns, which are large vertical vessels where the separation of air components occurs through cryogenic processes. Thermocouples can be used to measure the temperature at different points along the height of the distillation column to monitor and control the temperature profiles. This information is essential for optimizing the separation process and maintaining the desired product purity.

Heat exchanger temperature measurement: ASUs use various heat exchangers for cooling and condensing the separated gasses. Thermocouples can be used to measure the temperature of the cooling media, such as liquefied gasses or other coolants, and the temperatures of the separated gasses at different stages of the heat exchanger. This information is critical for maintaining efficient heat exchange, preventing overheating or freezing, and ensuring safe operation of the heat exchanger.

Product gas temperature measurement: Thermocouples can also be used to measure the temperature of the product gasses, such as nitrogen, oxygen, and argon, as they are collected and transferred within the ASU. Accurate temperature measurement of the product gasses is important for quality control, process optimization, and safety considerations.

Cryogenic temperature measurement: ASUs operate at very low temperatures, typically ranging from -150°C to -200°C or even lower, depending on the specific process and equipment. Thermocouples designed for cryogenic applications can be used to measure the temperatures of the cryogenic fluids, such as liquid nitrogen, liquid oxygen, or liquid argon, to ensure proper handling, storage, and utilization of these extremely cold gasses.

The specific details of an air-separation process may vary depending on the specific ASU design and application.

Key Takeaways:

- ASUs have become essential for various industries.

- The two types of air-separation plants are cryogenic and non-cryogenic. The former are preferred because they can produce high-purity nitrogen and oxygen.

- Some of the industries that use this technology are oil & gas and food & beverages.

- Type T thermocouples are stable at low temperatures and can perform well with a high level of accuracy without oxidizing in the presence of moisture

Thermocouples used in ASUs are typically designed to withstand the low temperatures, high pressures, and corrosive environments associated with cryogenic processes.

Proper installation, calibration, and maintenance of thermocouples are essential to ensure accurate and reliable temperature measurement in air separation units.

Overall, ASUs will continue to play an increasing role in an array of modern industries. For more information on these units, contact our team of experts today.