Ever wondered what would happen if a refinery or a petrochemical company selected and installed the wrong thermocouple at a station that was critical to the final outcome of their products? What do you think the quality would be? Most likely subpar, with threats to the safety of workers in such environments.

Now that you have an idea of what happens when you select the wrong thermocouple type and color code, you may wonder how you can tell which thermocouples are perfect for which temperature range.

Understanding which thermocouple to use is not a one-way street. It requires experience, practice, you keeping tabs on the latest innovations, and other factors we’ll discuss later in this article.

First, let’s take a look at what thermocouples are and what they are not.

What Are Thermocouples?

Thermocouples are simple devices used to measure temperature. The typical thermocouple consists of two wires of different metals and ends connected at a single point, widely called the thermal junction. We say “widely” because it is not uncommon to hear experts call it other names like the hot junction, the measurement junction, or the sensing point.

Depending upon the composition of the individual metals in each leg, an “EMF” (millivoltage) is developed which is a function of the difference in temperature between the two junctions.

Because a thermocouple generates a voltage that is proportional to temperature differences rather than to absolute temperature, it is necessary to fix one of the junctions at a known temperature for repeatable and accurate measurements. This fixed isothermal connection is called the reference or cold junction.

The range and accuracy of temperature measurements depend upon the conductor materials employed. Pairs of various metal alloys will react differently with changes in temperature.

Because a thermocouple consists of only two wires joined at the measuring junction or hot end, it is physically and inherently simple. A thermocouple can be made large or small depending on the requirements such as life expectancy, drift and response time. It may be flexible or rugged and is generally easy to handle and install.

Unlike many temperature transducers, a thermocouple does not encounter the problem of “self-heat.”

Why Shouldn’t You Use a Regular Thermometer Instead?

Measuring temperature for industrial and manufacturing can be tricky. While thermal measurement may be the goal, you also have to consider how replicable the results can be, the sensor’s durability, and the temperature range.

Here are a few reasons why thermocouples are the industrial temperature sensor of choice:

- Measure vast temperature ranges

- Withstand vibrations and corrosion if properly coated

- Have a fast read time for temperature changes

- Quickly reproduce temperature measurements for a wide range

- Don’t need an external current source to power thermocouples

Types of Thermocouple and ANSI Color Codes

We mentioned earlier that the wires of thermocouples are made from dissimilar metals. However, several metals can be used as thermocouple wires — and they can be combined to cater to your custom temperature-sensing needs.

These combinations are of eight different types. However, all eight thermocouple types and their individual properties can be challenging to track, especially for the untrained person.

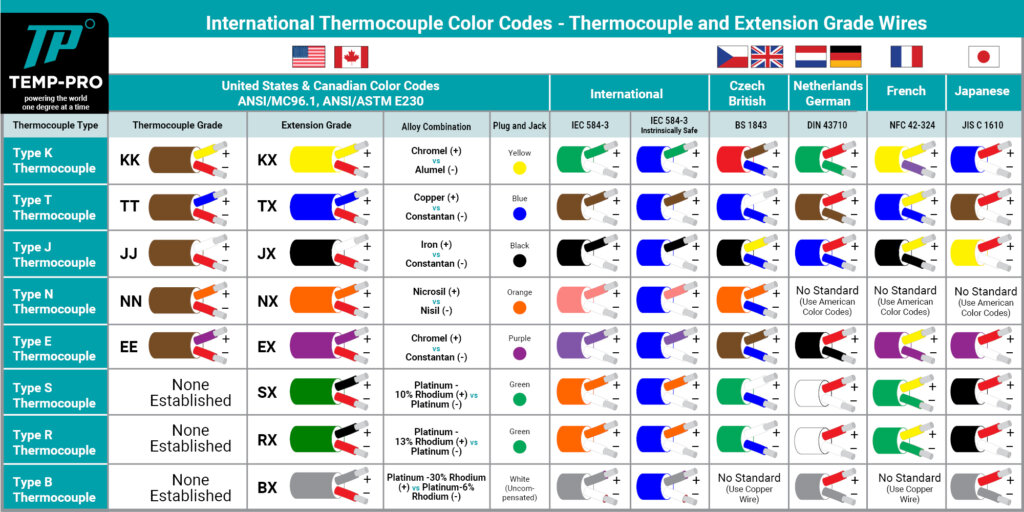

ANSI color codes were introduced to help expert and amateur personnel easily identify thermocouple types. Even though there are other international standards for grading wire in thermocouples, ANSI standards are the most widely accepted in the United States and Canada.

As we explain further, you’ll hear terms like “extension grade” and “thermocouple grade.” The former references the color grading of the wire insulation and jacket at the sensing junction, and the latter represents the color grades for insulated wires and jackets extending from the measuring point back to the reading instrument.

Note that the thermocouple jackets are always brown where applicable, and the negative leads red. Here are the types of thermocouples:

Type B Thermocouple

Type B thermocouples are most suitable for high-temperature manufacturing processes; their temperature range is convenient, measuring between 870℃ and 1700℃. There are no peculiar thermocouple grade colors; the extension grade jacket and the positive lead are gray.

Type B are used in inert or oxidizing atmospheres, or for a short period of time in a vacuum. To protect against contamination, the wires must be protected from the effects of reducing atmospheres and contaminating vapors. Alumina protection tubes are recommended for the protection of the wires.

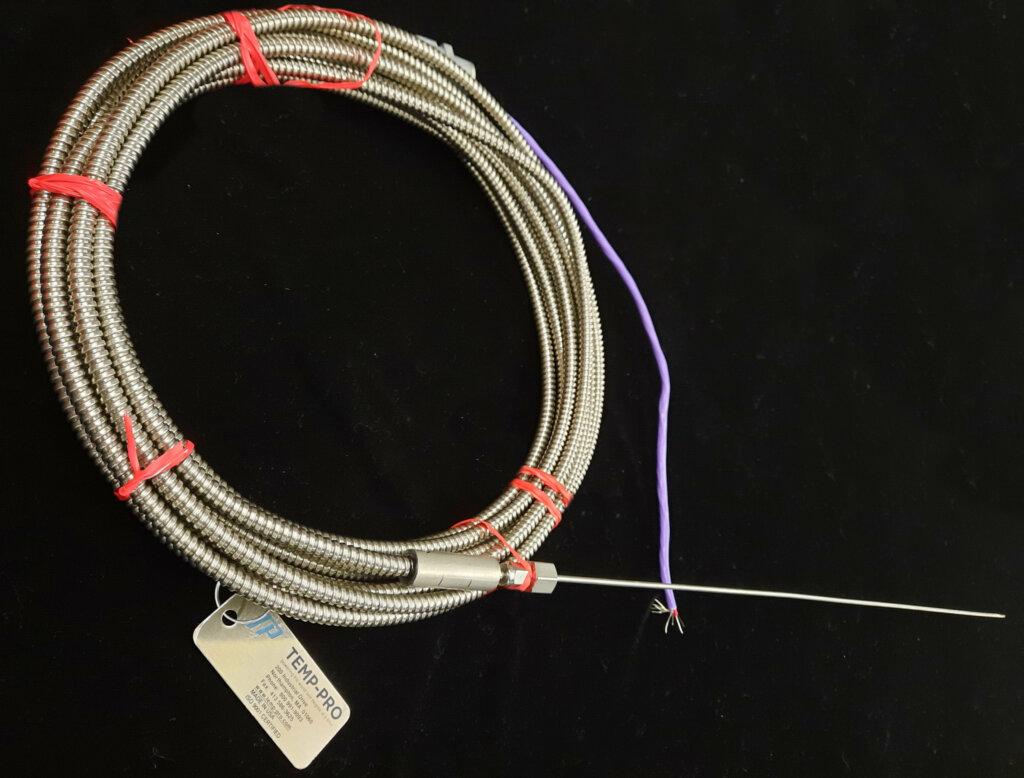

Type E Thermocouple

Type E Thermocouple

The temperature range for Type E thermocouples is between -200℃ and 900℃. Although they may be ideal for an inert and continuously oxidizing environment, they can’t stand sulfur. Type Es are known to have purple extension jackets and positive leads.

Type E may be used protected or unprotected in oxidizing, inert or dry reducing atmospheres, for a short time in a vacuum. They must be protected from sulfurous and marginally oxidizing atmospheres. They produce the highest EMF per degree of any standard thermocouple.

Type J Thermocouple

Type J thermocouples function best between 0℃ and 760℃ in an inert environment. They slowly become inaccurate with consistent temperature measurements above the 760℃ limit. The positive lead is white, and the extension jacket is colored black.

Type J thermocouples can be used protected or unprotected in a vacuum, oxidizing, inert or reducing atmospheres. The iron leg oxidizes rapidly at temperatures exceeding 1000 degrees Fahrenheit; therefore, a heavier gauge wire is recommended for longer life at these temperatures.

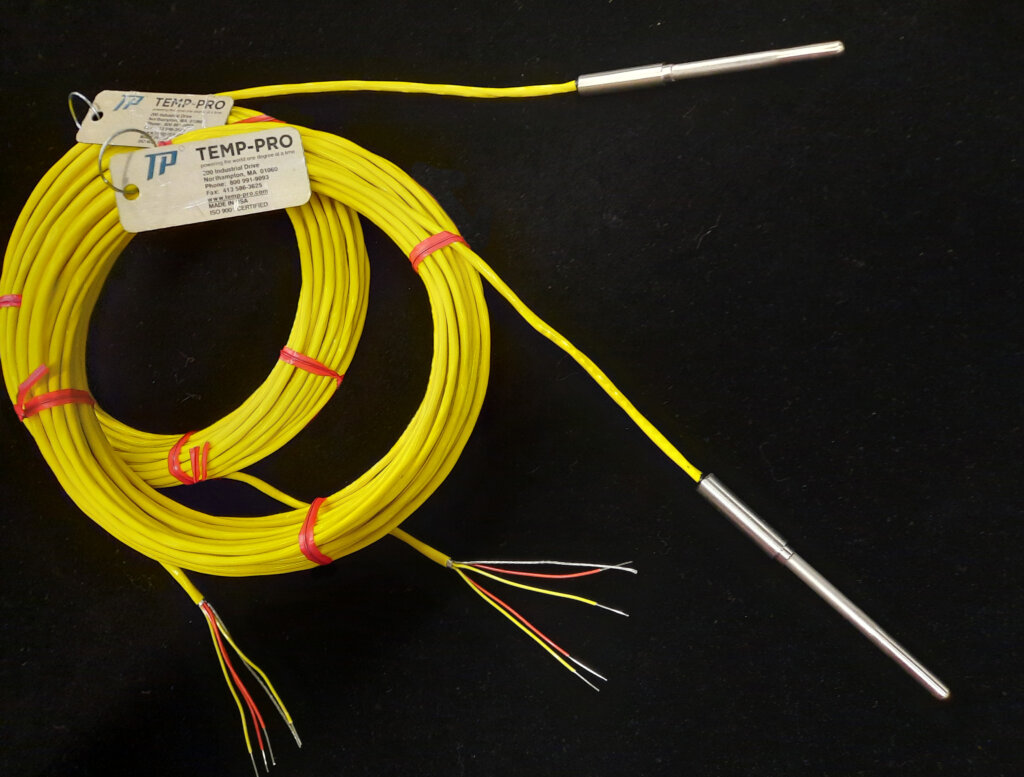

Type K Thermocouple

Type K Thermocouple

You may experience that your Type K thermocouples’ lifespan reduces if you continuously use them in near inert and oxidizing materials. They cope well in extreme heat with a temperature range between -200℃ and 1260℃. You can easily identify a Type K by its yellow positive lead and brown extension.

Type K thermocouples may be used to protect or expose oxidizing, inert, or dry reducing atmospheres. Although they are reliable and accurate at high temperatures, they must be protected from sulfurous and marginally oxidizing atmospheres and exposure to vacuum is limited to short time periods.

Type N Thermocouple

N-types are great for petrochemical industries with a narrow temperature measuring range of 0℃ to 1260℃ and resistance against green rot. Look out for the orange extensions and positive leads if you’re in the market for one.

Type R Thermocouple

Type R thermocouples are widely reputed for their accuracy, stability, and high measuring temperature of 1450℃, qualities that sulfur recovery unit personnel look out for. Typically, they’re color-coded green for the extensions and black for the positive lead, but with no peculiar thermocouple color grading.

Type R, like Type B are used in inert or oxidizing atmospheres, or for a short period of time in a vacuum. To protect against contamination, the wires must be protected from the effects of reducing atmospheres and contaminating vapors.

Type S Thermocouple

Type S Thermocouple

Type S thermocouples are similar to Type R with the same ranges up to 1450. The thermocouple wire color coding and characteristics are the same as in Type R.

Type T Thermocouple

Type T thermocouples have a temperature range of -200℃ to 350℃. Their lower temperature range makes them perfect for extreme applications like cryogenics. Plus, they can withstand wet conditions. T-types are known for their blue extensions and positive leads.

Type T thermocouples may be used for service in oxidizing, inert or reducing atmospheres, or in a vacuum. It is highly resistant to corrosion from atmospheric moisture and condensation and exhibits high stability at low temperatures. It is the only type with limits or error guaranteed for Cryogenic temperatures.

What to Consider When Buying a Thermocouple

If we could rely on temperature range alone, buying a thermocouple would be a breeze — but that’s not the case. You have to consider other factors, like durability. Here are three factors to consider before shopping for a thermocouple:

- Have an idea of your manufacturing process and the materials involved in the production.

- Determine the temperature range and check for fluctuations, if any.

- Note the importance of response time in your manufacturing process.

You may need a professional’s help to determine which is best for your business, to prevent choosing the wrong type and running into thermocouple failures.

A thermocouple normally covers a wide range of temperatures and its output is reasonably linear over portions of that range. Thermocouples of the same type are interchangeable within specified limits of error.

Temp-Pro has a calibration laboratory for calibration and verification of Temperature vs. EMF of the thermocouples supplied to the customers and provides calibration data when requested by the customer.

Takeaways

- Thermocouples are great for industrial use as they are durable, affordable, and accurate.

- You can quickly identify thermocouple types based on ANSI’s color coding.

- Temperature alone is not a sufficient criterion for choosing a thermocouple.

- Consider response times and materials alongside the temperature range.

Contact Temp-Pro, the Temperature Experts, for All Your Thermocouple Needs

Doing the most audacious and amazing things sometimes requires an equally spirited partner who understands you and your goal.

Temp-Pro has been at the center of many innovations for more than 50 years, consulting for innovators and providing them with custom temperature sensors that meet and exceed the international standard where regular solutions may not be the most appropriate.

What are your thermocouple needs? Tried other solutions that never fit into your production setup? Temp-Pro has the most reliable thermocouples in store and after-service that Fortune 500 companies would envy. Contact Temp-Pro at (800)-991-9093 for a quote today.