Small Modular Reactors

Small Modular Reactors (SMRs) are crucial to developing reliable, low-cost nuclear power options. SMRs in the US come in many sizes, employ many different technologies, and have a wide variety of capabilities in many different deployment situations. High-powered reactors can generate power, process heat, desalinate, and more. SMR designs can use soft water, gas, liquid metal, or molten fluoride salt as coolant.

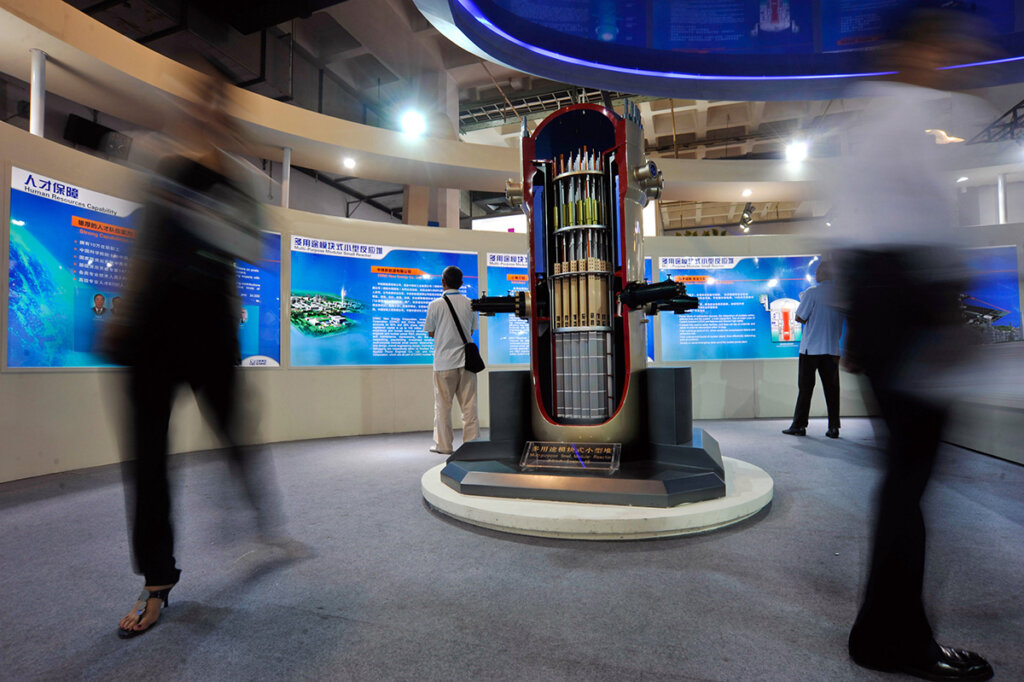

What are Small Modular Reactors?

SMRs are nuclear reactors that generate less than 300 MWe equivalent in power and are designed with modular technology using module factory fabrication. SMRs aim to achieve economies of scale and short construction times.

A desire to lessen the impact of capital costs and a need to generate power that is not connected to extensive grid systems for remote areas are driving the interest in small- and medium-sized nuclear power reactors. Because of their modular nature, you can assemble systems and their constituent parts in a factory setting before shipping them to their final installation site.

SMRs can be less bulky, simpler to operate, and afford a longer time period between refills. SMRs are considered to be a far more manageable investment than large nuclear power plants.

Industries That Use Small Modular Reactors

These advanced reactors can be utilized for power generation, the provision of process heat, the desalination of water, and several other industrial applications. In a hybrid energy system, Solid-State Microwave Reactors could be combined with renewable energy sources to boost their overall efficiency.

Types and Uses of Small Modular Reactors

Light-water nuclear energy reactors are pressurized, forcing high-pressure primary coolant into the reactor core. Atomic fission heats the primary coolant. Its solid fissile fuel is cooled and moderated by light water.

Fast-Neutron Reactors (FNRs) are more compact and less complicated than light-water reactors. They also offer superior fuel performance and can go longer before refueling is needed (up to 20 years). The high temperature at which they operate benefits their thermodynamic efficiency.

High Temperature Reactors (HTRs) use graphite as the moderator (except fast-neutron variants) and helium, carbon dioxide, or nitrogen as the main coolant. Due to their use of passive decay heat removal and their negative temperature coefficient of reactivity, which causes the fission reaction to slow down as the temperature rises, the reactors are inherently safe.

Molten Salt Reactors are an additional subtype of solid-state nuclear reactors. Molten salt reactors remove the heat created within the reactor by applying low pressure to chemicals such as magnesium chloride or lithium fluoride.

The rugged temperature sensors like those manufactured by Temp-Pro are reliable in operating conditions of an advanced SMR that uses natural water circulation to cool the reactor. Sensor response time is needed to detect changes in the coolant conditions that would require the reactor to safely shut down. Temp-Pro’s team of engineers can help you with the selection of RTDs suitable for safety-related temperature measurements of the reactor coolant and main steam of small modular reactors.

Temp-Pro has complete custom design and manufacturing capabilities to assist you in any temperature sensing requirement. Sensors can be manufactured provided we receive a drawing, sketch or failed part.

Temp-Pro can custom design and develop instrumentation and control (I&C) system sensor and cable solutions to assure the safe, reliable, and efficient operation of SMRs throughout their service lifetimes.

The performance of temperature sensors is dependent on several factors, including plant operating conditions. In particular, the plant operation can affect the static or accuracy and dynamic or response performance of the sensor, whereas the surrounding ambient environment can impact the remaining useful life of cable assemblies, connectors, and other associated components.

The safe and efficient operation of any nuclear power plant depends on accurate and timely measurement of the primary system’s temperature.

We offer redundant thermowell-mounted RTDs on both sides of the reactor, on the top for hot leg temperature measurement and on the bottom for cold leg temperature measurement.

Measurement of Air and Steam Temperature is critical, RTDs will be used to measure temperature in steam or air processes Main Steam (MS) temperature.

Some Specific SMR Instruments:

ETU Multipoint Thermocouples (Vessel Sys. PDR)

RTDs, Thermocouples, Thermowells for inline temp measurement

Relief Line Temperature

IDT Argon Inlet Temperature

Key Takeaways

- Small Modular Reactors (SMRs) are modular nuclear reactors that generate power less than 300 MWe equivalent and are the product of module factory fabrication.

- Fast-Neutron Reactors (FNRs) are smaller and simpler than light-water reactors and are capable of better fuel performance and longer refueling intervals (up to 20 years).

- High Temperature Reactors (HTRs) use graphite as the moderator (save for fast neutron types) and helium, carbon dioxide, or nitrogen as the primary coolant.

- Molten salt reactors remove heat generated within the reactor by applying low pressure to substances such as magnesium chloride or lithium fluoride.

SMRs come with several benefits: a lower capital expenditure, the ability to be sited in regions where you cannot build larger nuclear reactors, and options for supplemental electrical power generation for systems uamps. Contact Temp-Pro today for the best Small Modular Reactor temperature sensor support.