A thermocouple is a device that measures temperature by generating an electrical current with a temperature-dependent voltage. This voltage may then be interpreted to determine its temperature. A thermowell is a structure that surrounds a thermocouple to protect it from damaging elements such as liquid or corrosive materials. Thermowells also increase the thermocouple’s longevity by allowing the thermocouples to be replaced without draining the entire system, thus reducing the probability of contamination. Thermowells designed for low-pressure environments are often made from tubing with one end welded closed, but high-pressure thermowells are typically machined from bar stock for greater strength.

Temp-Pro works with customers to ensure their equipment meets their requirements with respect to thermocouples, including response times. This process often involves deciding whether to integrate a thermowell into the equipment or use a wall for the fitting. Our experience in designing custom temperature measurement solutions takes process parameters such as response time goals into account, playing a major role in a thermocouple’s performance and longevity. This approach allows us to determine how to choose a thermowell that best meets your needs.

1. How can people choose the best thermowell for their application?

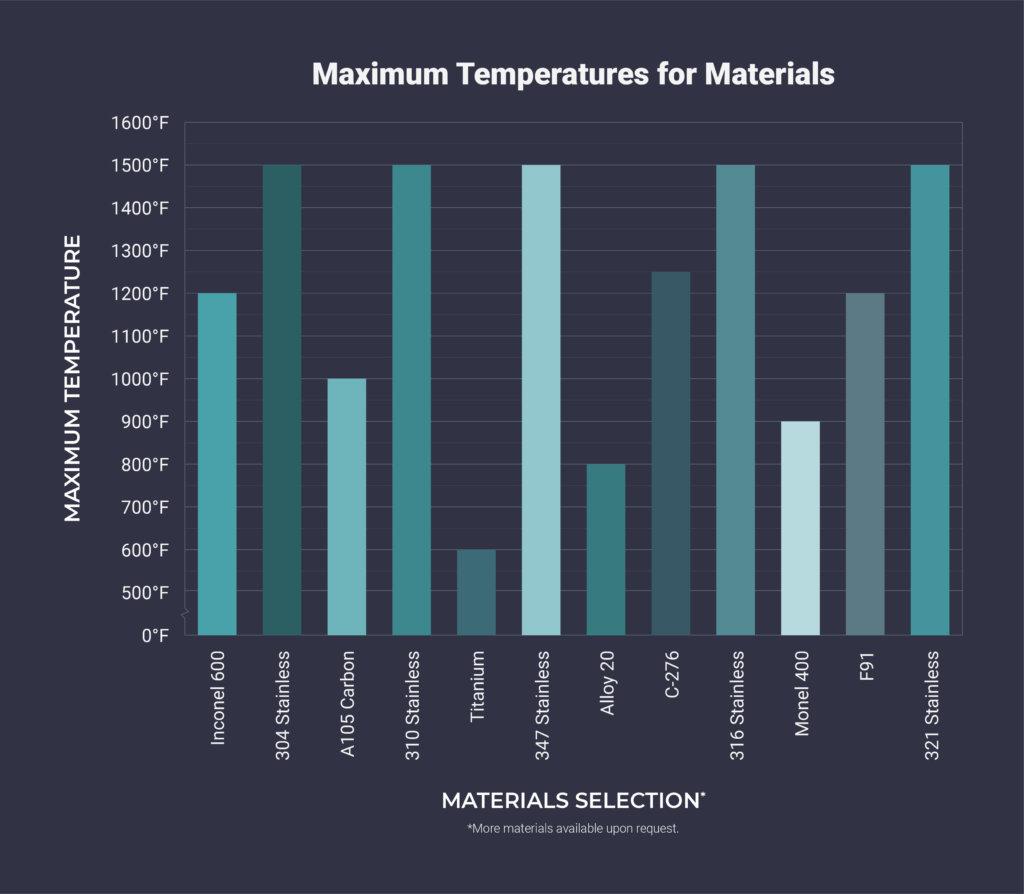

A thermowell’s longevity primarily depends on its material and operating environment, including chemicals, temperature and flow rate. The selection of material is crucial, especially for environments with both high temperature and chemicals. Fluids containing suspended particles are also highly damaging to thermowells.

Stainless steel contains chromium and is the most common material for thermowells, since it’s cost effective and highly resistant to heat and corrosion. The addition of molybdenum increases the strength and corrosion resistance of stainless steel, making it useful for pressurized vessels. A Haynes alloy is a type of stainless steel that contains cobalt, nickel and tungsten, which is commonly used for thermowells in environments where carbon, chlorine or sulfur reacts with steel. High carbon steel has a lower resistance to corrosion than stainless steel, so its applications are limited to environments of low temperature and pressure. Temp-Pro’s thermowells are designed for a variety of applications, like process markets, chemical and petrochemical plants, water and wastewater pressure control, refineries and power. They are also used in the industrial market in turbines and compressors and equipment skids.

If you aren’t entirely sure on the thermowell you need, the expert engineers at Temp-Pro are here to help you select the best thermowell for your application.

2. Does Temp-Pro provide thermowell installation services?

Temp-Pro provides thermowell installation services, including wake frequency calculations to ensure the thermowells provide optimal operational performance. These calculations comply with the latest ASME PTC19.3 TW-2016 standard for vibrations, which is a critical design consideration for thermowells. Wake calculations help design engineers evaluate the construction and installation of thermowells by measuring the data needed to evaluate them under real-world operating conditions.

Our wake frequency calculations account for variables in fluid properties and pipe specifications. They also consider data related to the thermowell itself, such as its connection and mounting type. Additional factors that engineers need to provide a detailed technical report on thermocouples include their bore, root and tip diameters.

3. Are thermowells used in combination with temperature sensors?

Thermowells are routinely used with temperature sensors like thermocouples. This application requires a pressure-tight fitting to maximize the thermocouple’s operational lifetime and accuracy in measuring temperature. Thermowells also allow engineers to remove and inspect thermocouples more easily during maintenance and replacement. Temp-Pro can design a complete range of industrial temperature measurement devices for any equipment, regardless of its configuration, size or type.

4. What are the major differences between the types of thermowells on the site?

Thermowell types include straight, tapered and stepped designs. Straight thermowells have a constant diameter throughout their entire insertion length, providing better protection against corrosion. The diameter of tapered thermowells decreases gradually over their insertion length, providing greater strength and faster response to temperature changes. Stepped thermowells have diameters that decrease at specific intervals from the top to the tip, allowing for smoother fluid flow.

Takeaways

Many industrial processes use thermowells to measure temperature in harsh operating conditions. The best material for these devices depends on the application as follows:

- Stainless steel – cost-effective for most applications requiring heat and corrosion resistance

- Molybdenum stainless steel – pressurized vessels

- Haynes alloys – corrosive environments

- High-carbon steel – low temperature and pressure

Temp-Pro handles temperature measurement projects of any complexity and industry. Our aftermarket and custom products include thermocouples, thermowells, thermistors and transmitters. Contact us online or call 1-800-991-9093 today to learn more about how we can meet your temperature sensor needs.