Understanding Corrosion: A Complex Dance with Materials

Corrosion, in its essence, is a natural chemical reaction between materials and their surrounding environment. It involves the gradual degradation of metals and alloys due to various factors such as moisture, chemicals, temperature fluctuations, and exposure to gases. While corrosion can sometimes be harnessed beneficially, such as in the case of creating protective oxide layers, it more commonly poses a significant threat to industrial equipment and processes.

The Diverse Faces of Corrosion

The spectrum of corrosion mechanisms is vast and can include uniform corrosion, pitting corrosion, crevice corrosion, and stress corrosion cracking, among others. The selection of materials and protection strategies hinges on understanding the specific corrosion process taking place, the materials involved, and the unique demands of the application.

Role of Temperature Sensors: Vital but Vulnerable

Role of Temperature Sensors: Vital but Vulnerable

In the grand tapestry of industrial processes, the need for accurate temperature monitoring cannot be overstated. Yet, this precision must be achieved despite the often corrosive and hostile environments in which these processes occur.

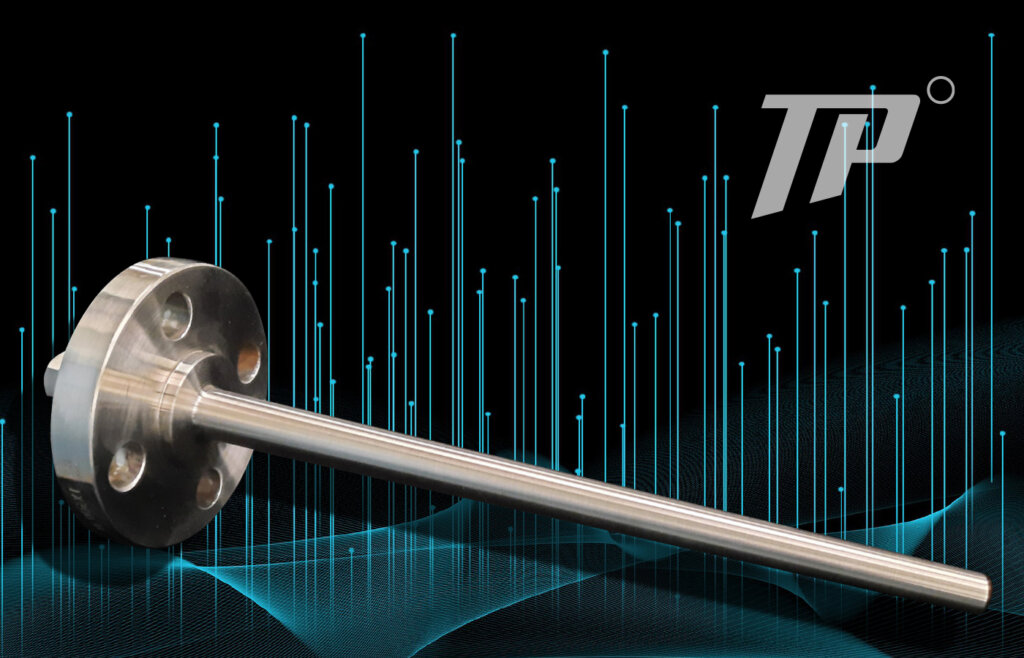

Enter the Thermowell: Armor Against Corrosion

A thermowell, a critical component in temperature sensing systems, is a protective sheath designed to encase temperature sensors, ensuring their reliability and longevity in corrosive environments. Typically manufactured from corrosion-resistant materials like stainless steel, Inconel, or Hastelloy, thermowells act as a barrier, preventing direct contact between the sensor and the corrosive medium.

By intelligently selecting the proper thermowell material, design, and installation, industrial operations can effectively guard against corrosion-driven sensor failures, safeguarding their processes, maintaining efficiency, and ensuring product quality.

As industries continue to evolve and push boundaries, thermowells will remain a crucial element in maintaining efficiency, safety, and product quality. Through these unassuming protective sheaths, industrial processes can continue to thrive in the face of corrosion’s relentless forces.

The following chart lists the most common corrosion-susceptible materials used in thermowells. The second column lists the temperature in Fahrenheit at which it corrodes. The third column is the percentage of concentration, and the last column contains the corrosion-resistant materials that are recommended for use with these susceptible materials.

Thermowells can protect your temperature sensing systems from the challenges of corrosion. Additionally, with helical thermowell technology, companies can ensure even more accuracy and eliminate concerns about failure within high velocity environments. Some common helical thermowells are made from 304 stainless Steel, 316 stainless Steel, and Monel, but there are many materials to choose from according to your process needs.

Temp-Pro offers a wide range of temperature control equipment and services, including industrial temperature sensors such as RTDs, thermocouples, helical thermowells, and industrial electrical enclosures. Our team of experts is dedicated to meeting your unique needs and exceeding your expectations. Contact us today and get a customized solution to suit your business needs.

| CORROSIVE | TEMP F | CONC. % | RECOM. MATERIAL |

| Acetic Acid | 212 | ALL | Monel |

| Acetic Anhydride | 300 | Nickel | |

| Acetone | 212 | ALL | 304 SS |

| Acetylene | 400 | 304 SS | |

| Alcohols | 212 | ALL | 304 SS |

| Alum (Potassium or Sodium) | 300 | ALL | Hast. C |

| Aluminum Chloride | 212 | ALL | Hast. B |

| Aluminum Sulfate | 212 | ALL | 316 SS |

| Ammonia, Dry | 212 | ALL | 304, 316 SS |

| Ammonium Hydroxide (Ammonia, Aqua) | 212 | ALL | 304, 316 SS |

| Ammonium Chloride | 300 | 50% | Monel |

| Ammonium Nitrate | 300 | ALL | 304 SS |

| Ammonium Sulfate | 212 | ALL | 316 SS |

| Amyl Acetate | 300 | ALL | 304 SS |

| Aniline | 75 | Monel | |

| Asphalt | 250 | 304 SS | |

| Atmosphere (Industrial and Marine) | 304 SS | ||

| Barium Compounds SEE CALCIUM | |||

| Beer | 70 | 304 SS | |

| Benzene (Benzol) | 212 | Steel | |

| Benzoic Acid | 212 | ALL | 316 SS |

| Bleaching Powder | 70 | 15% | Monel |

| Borax | 212 | ALL | Brass |

| Bordeaux Mixture | 200 | 304 SS | |

| Boric Acid | 400 | ALL | 316 SS |

| Bromine | 125 | DRY | Monel |

| Butane | 400 | ALL | Steel |

| Butyl Alcohol | SEE ALCOHOLS | ||

| Butyric Acid | 212 | Hast. C | |

| Calcium Bisulphite | 75 | ALL | Hast. C |

| Calcium Chloride | 212 | ALL | Hast. C |

| Calcium Hydroxide | 300 | 20% | Hast. C |

| Calcium Hypochlorite | SEE BLEACHING POWDER | ||

| Carbolic Acid | SEE PHENOL | ||

| Carbon Dioxide, Dry | 800 | ALL | Brass |

| Carbonated Water | 212 | ALL | 304 SS |

| Carbonated Beverages | 212 | 304 SS | |

| Carbon Disulfide | 200 | 304 SS | |

| Carbon Tetrachloride | 125 | ALL | Monel |

| Chlorine, Dry | 100 | Monel | |

| Chlorine, Moist | 100 | ALL | Monel |

| Chloracetic Acid | 212 | ALL | Monel |

| Chloroform, Dry | 212 | Monel | |

| Chromic Acid | 300 | ALL | Hast. C |

| Cider | 300 | ALL | 304 SS |

| Citric Acid | 212 | ALL | Hast. C |

| Copper (10) Chloride | 212 | ALL | Hast. C |

| Copper (10) Nitrate | 300 | ALL | 316 SS |

| Copper (10) Sulfate | 300 | ALL | 316 SS |

| Copper Plating Solution (Cyanide) | 180 | 304 SS | |

| Copper Plating Solution (Acid) | 75 | 304 SS | |

| Corn Oil | 200 | 304 SS | |

| Creosote | 200 | ALL | 304 SS |

| Crude Oil | 300 | Monel | |

| Ethyl Acetate | SEE LACQUERS AND THINNERS | ||

| Ethyl Chloride, Dry | 500 | Steel | |

| Ethanol | SEE ALCOHOLS | ||

| Ethylene Glycol (Uninhibited) 212 | ALL | 304 SS | |

| Ethylene Oxide | 75 | Steel | |

| Fatty Acids | 500 | ALL | 316 SS |

| Ferric Chloride | 75 | ALL | Hast. C |

| Ferric Sulfate | 300 | ALL | 304 SS |

| Formaldehyde | 212 | 40% | 316 SS |

| Formic Acid | 300 | ALL | 316 SS |

| Freon | 300 | Steel | |

| Flourine, Anhydrous | 100 | 304 SS | |

| Furfural | 450 | 316 SS | |

| Gasoline | 300 | Steel | |

| Glucose | 300 | 304 SS | |

| Glue ph 6-8 | 300 | ALL | 304 SS |

| Glycerine | 212 | ALL | Brass |

| Hydrobromic Acid | 212 | ALL | Hast. C |

| Hydrochloric Acid (37-38%) | 225 | ALL | Hast. B |

| Hydrogen Chloride, Dry | 500 | 304 SS | |

| Hydrocyanic Acid | 212 | ALL | 304 SS |

| Hydroflouric Acid | 212 | 60% | Monel |

| Hydrogen Flouride, Dry | 175 | Steel | |

| Hydrofluogilicic Acid | 212 | 40% | Monel |

| Hydrogen Peroxide | 125 | 10-100% | 304 SS |

| Kerosene | 300 | ALL | Steel |

| Lacquers and Thinners | 300 | ALL | 304 SS |

| Lactic Acid | 300 | ALL | 316 SS |

| Lime | 212 | ALL | 316 SS |

| Linseed Oil | 75 | Steel | |

| Magnesium Chloride | 212 | 50% | Nickel |

| Magnesium Hydroxide (or Oxide) | 75 | ALL | 304 SS |

| Magnesium Sulfate | 212 | 40% | 304 SS |

| Mecuric Chloride | 75 | 10% | Hast. C |

| Mercury | 700 | 100% | Steel |

| Methylene Chloride | 212 | ALL | 304 SS Methyl Chloride, Dry |

| Milk, fresh or sour | 180 | 304 SS Molasses | |

| Natural Gas | 70 | 304 SS | |

| Nitric Acid | 75 | ALL | 304 SS |

| Nitric Acid | 110 | ALL | 316 SS |

| Oxygen | 75 | ALL | Steel |

| Potassium Compounds | SEE SODIUM COMPOUNDS | ||

| Propane | 300 | Steel | |

| Rosin | 700 | 100% | 316 SS |

| Sea Water | 75 | Monel | |

| Soap and Detergents | 212 | ALL | 304 SS |

| Sodium Bicarbonate | 212 | 20% | 316 SS |

| Sodium Bisulphite | 212 | 20% | 304 SS |

| Sodium Bisulphate | 212 | 20% | 304 SS |

| Sodium Carbinate | 212 | 40% | 316 SS |

| Sodium Chloride | 300 | 30% | Monel |

| Sodium Chromate | 212 | ALL | 316 SS |

| Salt or Brine | SEE SODIUM CHLORIDE | ||

| Sodium Cyanide | 212 | ALL | 304 SS |

| Sodium Hydroxide | 212 | 30% | 316 SS |

| Sodium Hypochlorite | 75 | 10% | Hast. C |

| Sodium Nitrate | 212 | 40% | 304 SS |

| Sodium Nitrite | 75 | 20% | 316 SS |

| Sodium Phosphate | 212 | 10% | Steel |

| Sodium Silcate | 212 | 10% | Steel |

| Sodium Sulfate | 212 | 30% | 316 SS |

| Sodium Sulfide | 212 | 10% | 316 SS |

| Sodium Sulfite | 212 | 30% | 304 SS |

| Sodium Thiosulfate | 212 | ALL | 304 SS |

| Steam | 304 SS | ||

| Stearic Acid | SEE FATTY ACIDS | ||

| Sugar Solutions | SEE GLUCOSE | ||

| Sulfur | 500 | 304 SS | |

| Sulfur Chloride | 75 | DRY | 316 SS |

| Sulfur Dioxide | 500 | DRY | 316 SS |

| Sulfur Trioxide | 500 | DRY | 316 SS |

| Sulfuric Acid | 212 | 10% | 316 SS |

| Sulfuric Acid | 212 | 10-90% | Hast. B |

| Sulfuric Acid | 212 | 90-100% | 316 SS |

| Sulfuric Acid, Fuming | 175 | Alloy 20 | |

| Sulfurous Acid | 75 | 20% | 316 SS |

| Titanium Tetrachloride | 75 | ALL | 316 SS |

| Tannic Acid | 75 | 40% | Hast. B |

| Toluene | 75 | Steel | |

| Trichloracetic Acid | 75 | ALL | Hast. B |

| Trichlorethylene | 300 | DRY | Monel |

| Turpentine | 75 | 316 SS | |

| Varnish | 150 | Steel | |

| Zinc Chloride | 212 | ALL | Hast. B |

| Zinc Sulfate | 212 | ALL | 316 SS |