In the world of industrial equipment, temperature is a silent yet immensely influential factor in determining bearing performance.

Unveiling the Operational Dynamics of Fluid Film Bearings

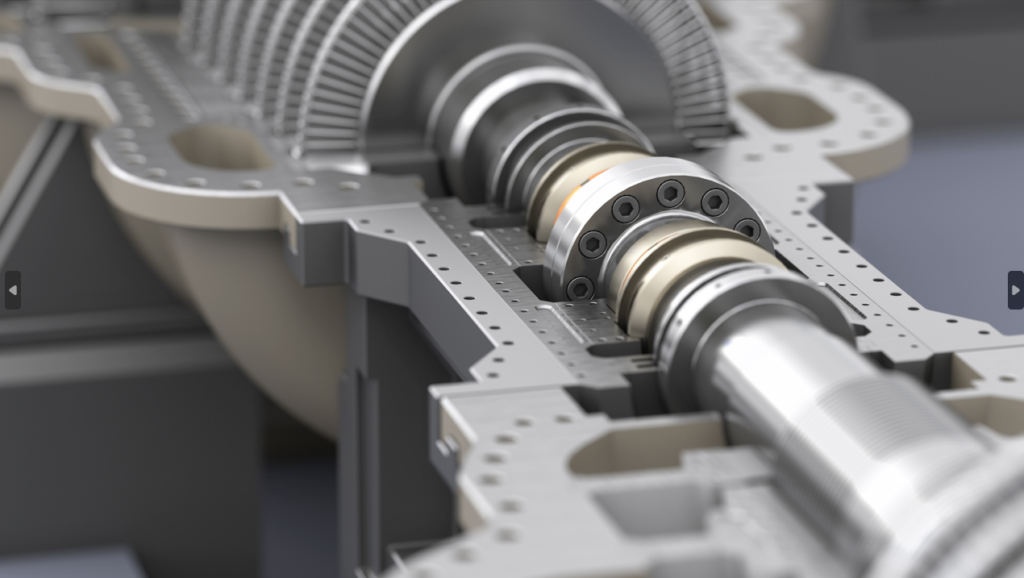

At the cutting edge of industrial machinery advancements, fluid film bearings are a masterpiece of engineering innovation. Their functionality revolves around the introduction of a fine layer of lubricant—typically oil—between the bearing surfaces. This lubricant layer effectively halts damaging metal-to-metal contact, resulting in a significant reduction in friction and wear. This distinguishing design empowers them to shoulder high loads and resist shock loading, making them an irreplaceable component in large, high-speed rotating machinery.

The Pivotal Role Temperature Plays in Fluid Film Bearings

The Pivotal Role Temperature Plays in Fluid Film Bearings

Temperature monitoring is crucial to the optimal performance of fluid film bearings. These sensors provide real-time temperature measurements, enabling proactive maintenance, preventing costly machinery failures, and ensuring operational efficiency. Escalated temperatures can compromise the lubricating fluid’s quality, potentially leading to bearing failure. Furthermore, anomalies in temperature distribution, such as unusually hot spots, could indicate underlying complications such as misalignment, overbearing load, or lubrication inadequacy.

The Importance of Thrust Bearings

Thrust bearings, a specific class of fluid film bearings, are precisely engineered to counter axial loads. Although available in a variety of forms, the tilting pad type emerges as a front-runner in terms of operational efficacy. Owing to their excellent stability and load-bearing capacity, tilting pad thrust bearings are a preferred choice in high-speed applications such as turbines, compressors, and gearboxes.

The Intricacies of Shoe Temperature Variations in Fluid Film Bearings

“Shoe temperature” denotes the temperature on the surface of a tilting pad or bearing shoe. Given the cardinal role that temperature plays in bearing performance, understanding and monitoring shoe temperature variations holds critical importance in any maintenance program. Irregularities in temperature variations could hint at potential problems such as pad misalignment, issues related to lubrication, or pad damage, serving as an early detection system against possible bearing failure.

The Benefits of Using Bearing Embedment Thermocouples and RTDs

Bearing embedment thermocouples and resistance temperature detectors (RTDs) offer a reliable solution for tracking shoe temperature in fluid film bearings. These technologically advanced temperature sensors provide accurate and continuous temperature readings, thereby enabling proactive maintenance measures and failure prevention. They are engineered to be inserted directly into the bearing pad, ensuring precise temperature measurements critical for assessing overall bearing health. Thermocouples are robust and can tolerate high temperatures, while RTDs are distinguished by their higher accuracy and stability across a broad temperature range.

The Pathway to a Proactive Maintenance Strategy

Comprehending shoe temperature variations in fluid film bearings is not merely about understanding intricate technical terminology. Instead, it holds a fundamental place in ensuring the efficiency, reliability, and longevity of your industrial machinery. Therefore, a shift from reactive to proactive strategies is essential for efficient maintenance planning. Relying on Temp-Pro for accurate and dependable temperature sensors allows you to effectively monitor bearing performance and circumvent costly machinery downtime.

Understanding the Synergy between Temperature Sensors and Fluid Film Bearings

Bearing embedment thermocouples and RTDs from Temp-Pro are not only efficient at temperature monitoring but also crucial to the integrity of fluid film bearings. These sensors are engineered to be inserted into the bearing pad, providing real-time, precise temperature measurements that are key to assessing overall bearing health. With their readings, it is possible to detect temperature spikes that might indicate excessive friction, inadequate lubrication, or overload conditions. This facilitates proactive interventions to mitigate issues before they escalate into severe problems.

Bearing Temperatures as Early Warning Signs

The shoe temperatures in fluid film bearings serve as an early warning system. A sudden increase or fluctuation in temperature may indicate a problem in the system long before any other symptom becomes noticeable. The role of a reliable temperature sensor, in this case, is to provide a quick and accurate temperature measurement, allowing for immediate attention and maintenance activities, avoiding potential machinery failure or extensive damage.

The Economic Implications

Investing in robust temperature monitoring solutions such as those offered by Temp-Pro is not just an operational decision—it’s an economic one. Equipment failure can result in expensive repairs, machinery downtime, lost productivity, and even safety hazards. By accurately monitoring bearing temperatures, companies can identify potential issues early, reducing the risk of catastrophic failures and associated costs. The importance of such a proactive approach cannot be underestimated in today’s fast-paced, efficiency-driven industrial environment.

Temp-Pro’s Significant Contribution in Temperature Sensor Manufacturing

Temp-Pro’s Significant Contribution in Temperature Sensor Manufacturing

Temp-Pro, since its founding in 1972, has been a leader in the field of industrial temperature sensor manufacturing. Our expertise lies in the design and manufacturing of high-quality bearing embedment thermocouples and RTDs. Our unwavering dedication to quality, combined with deep-rooted expertise, has earned us the trust of industries that rely on high-performing fluid film bearings. Our products ensure operational safety and longevity by facilitating accurate and reliable temperature monitoring.

Conclusion:

Temperature sensors are indispensable in fluid film bearings, playing a crucial role in the efficient and reliable operation of industrial machinery. These sensors provide real-time, accurate temperature measurements, facilitating proactive maintenance strategies that prevent costly machinery failures and downtime.

Choosing high-quality temperature sensors, such as Temp-Pro’s bearing embedment thermocouples and RTDs, ensures the longevity and efficiency of your fluid film bearings. By partnering with Temp-Pro, you gain access to our expertise, commitment to quality, and reliable temperature sensor solutions custom-designed for bearing monitoring.

Don’t leave the performance of your industrial machinery to chance. Invest in superior temperature sensors from Temp-Pro and experience the peace of mind that comes with knowing your bearings are monitored with precision and reliability. Contact us today to learn more about our temperature sensor solutions and how they can benefit your operations.