When it comes to plant shutdowns and outages, time is a resource. The moment a plant or unit comes out of service for an outage, it stops generating revenue. Shutdowns and outages that run over budget and past deadline can result in serious financial losses, along with keeping your plant offline for longer than expected.

Planned outages in power plants of all types and sizes such as Combined-Cycle Plants, Simple-Cycle Plants, Cogeneration Plants, Waste Energy Plants and Fossil Steam Power Plants give your facility an opportunity to complete important maintenance and repair work while production is paused.

Industries such as these often require planned outages to ensure preventive maintenance in scheduled intervals. This proactive effort reduces the potential for outage extension, which in turn reduces availability while keeping maintenance costs under control.

Temp-Pro works with customers to ensure a planned outage is a success. Our approach to planned outages is based on our direct experience working in industrial environments. Our goal is to be a trusted partner ensuring we provide the key resources needed. Access to our expertise and insight defines the quality we deliver in any planned outage.

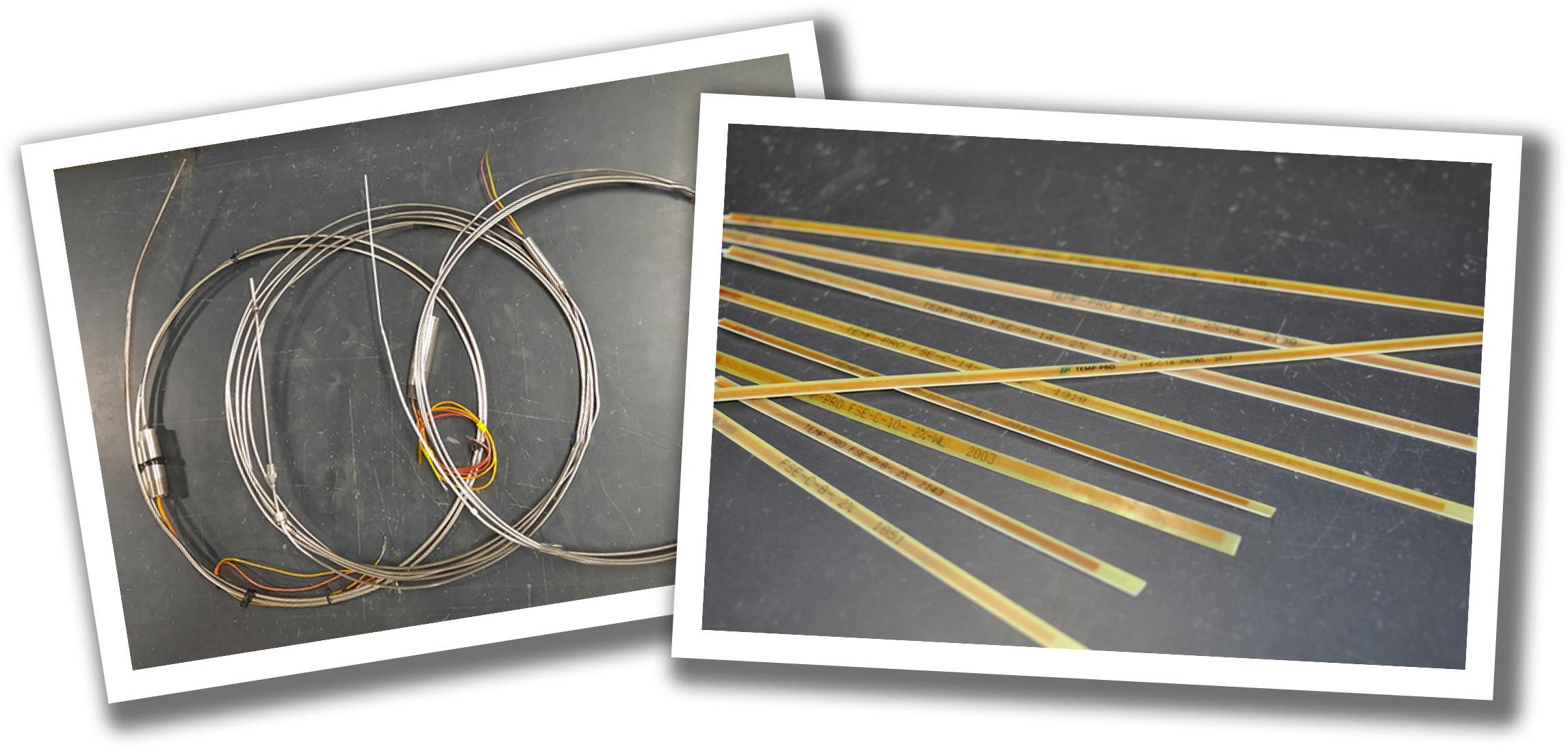

Being a valuable strategic partner to a wide range of power generation companies, we stress the importance of the periodic replacement of critical temperature and sensing elements.

Scheduled outages in the spring can be a good opportunity to inspect and replace a variety of sensors in power generation equipment. This includes:

- Steam Turbine Sensors: Bearing Sensors, Inner Case Sensors, Outer Case Sensors and Shell Sensors, Stator Resistance Thermometers

- Gas Turbine Sensors: Exhaust Gas Sensors, Blade Path Sensors, Wheel Space Sensors, Bearing Sensors, Embedment Sensors, Air Inlet Sensors and Oil Temperature Sensors

- Generator Sensors: Stator Resistance Thermometers in a variety of configurations (Single Element stator winding RTDs, Dual Element stator winding RTDs and Dual Independent Element stator winding RTDs) as well as materials—such as Copper, Platinum or Mixed.

Maximize your return on investments in outage projects with Temp-Pro’s expertise and insight so that your plant can return to service with minimal disruption to business.

Optimize your operational cost by improving plant performance with Temp-Pro exceling at meeting special requirements—including OEM design. We routinely manufacture custom sensors to be incorporated in a variety of equipment and machinery.

Increase the time between future outages to increase plant availability and reduce overall cost. Temp-Pro also offers a variety of options for our sensors, including Rear Exit, Side Exit, Paddle Sensors (also called Air or Gas RTDs), custom holes and sizes, electrically conductive coatings, and dual sensors with different elements.

Contact Temp-Pro today to help you manage through your scheduled Spring outages, our expertise in temperature sensing devices is beyond expectations.