Are temperature sensor accessories worth the investment?

Temperature sensors have saved industries money by monitoring and detecting any extreme temperature range that would impact machinery or cause breakdowns. Just as you buy a phone and you add on earbuds to complement it, there are also accessories for temperature sensors.

What are miscellaneous temperature sensors?

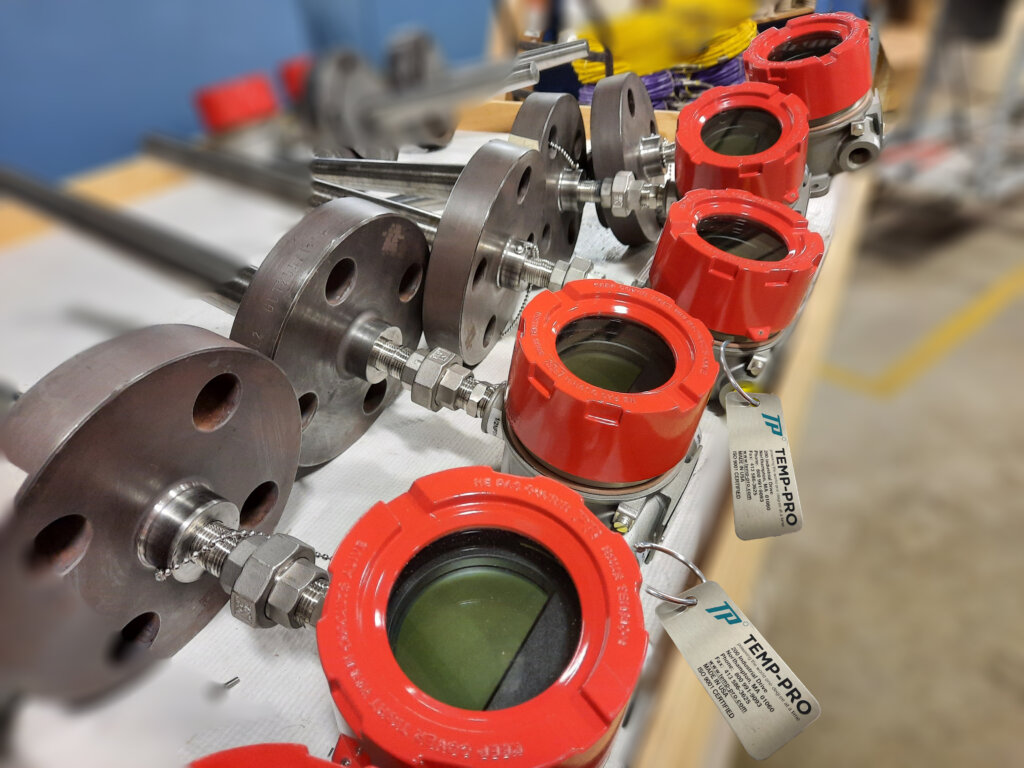

In addition to the standard temperature sensors such as RTDs, Thermocouples and Thermistors, Temp-Pro has complete custom design and manufacturing capabilities to assist you in any temperature sensing requirement. To complement our sensors, we offer a complete line of sensing related products and accessories.

Miscellaneous temperature sensors are developed to complement the temperature sensors in varied ways. These sensors include gas-actuated thermometers, pressure gauges, transmitters, and bimetal thermometers.

Gas Actuated Thermometers

These are mounted directly or remotely in thermowells for temperature measurement. They are known to give accurate readings because they use gas, and it has a more regular expansion. They are all stainless steel with a wide selection of temperatures (between -200 degrees to 700 degrees Celsius) and are also highly resistant to shock and vibrations.

These are mounted directly or remotely in thermowells for temperature measurement. They are known to give accurate readings because they use gas, and it has a more regular expansion. They are all stainless steel with a wide selection of temperatures (between -200 degrees to 700 degrees Celsius) and are also highly resistant to shock and vibrations.

Unlike negative temperature coefficient temperature sensors, their resistance does not decrease with increasing temperature. They are incredibly versatile and not restricted to thermowells. You can use them in other applications such as chemical plants, petrochemical plants, pulp, paper, water and wastewater, and machine construction.

Pressure Gauges

These are devices that help monitor performance parameters such as force and pressure. Pressure gauges are used in refineries, petrochemical plants, natural gas transmission, water, wastewater, mining and metals.

Pressure gauges are fluid intensity measurement devices. These devices help monitor performance parameters, pressure connections and pressure ranges.

A pressure gauge is a self-contained indicator that converts the detected process pressure into the mechanical motion of a pointer which is a method of measuring fluid, gas, water, or steam intensity in a pressure powered machine to ensure there are no leaks or pressure. Pressure gauges are necessary for setting up and regulating fluid power equipment, as well as troubleshooting them. Fluid power systems would be unpredictable and unreliable without pressure gauges. They verify that there are no leaks or pressure variations that could damage the hydraulic system’s operation.

Differential Pressure Gauges are used to monitor filtration, liquid level, and liquid flow. They are important in refineries, petrochemical and chemical factories, power plants, and clean rooms, among other places. The difference between two pressure readings is measured as differential pressure. It provides no information about the pressure levels at the two particular places it compares.

Gauge Pressure Measuring Devices are common pressure measuring equipment used in the power, refinery, chemical, petrochemical, pharmaceutical, food, refrigeration, air-conditioning, and sanitation industries. The gauge pressure is calculated using the standard atmospheric pressure at sea level as a reference.

Absolute Pressure Gauges are used to perform distillation operations in the oil refining industry. The pressure is determined by comparing it to the pressure in a complete vacuum. They can also be used to measure the vapor pressure of liquids, vacuum reactors, check leakage in tanks and circuits, and also measure the fall in pressure.

Pressure gauges are used in Refineries, Chemical and Petrochemical Plants, Offshore Oil and Gas, Natural Gas Transmission and LNG, Water and Wastewater, Power Generation, Mining and Metals Industries.

Transmitters

Transmitters convert signals produced by a resistance temperature detector or a thermocouple into a standard instrumentation signal and act as the interface between the temperature sensors and the display or control device. They require a power supply, and most have two wire types. The two wires provide power for the transmitters and also serve as signal lines.

There are also 4-wire transmitters with two wires connected to a power supply and two signals connected to the PLC. Temp-Pro offers transmitters for RTDs and Thermocouples. For RTDs – PT100 or custom inputs with 2, 3 and 4 wire configurations. Some examples of industries where transmitters are used are aerospace, chemical, food & beverage, energy, pharmaceuticals, petrochemicals to name a few.

The ranges of the transmitters can be factory set to standard or custom ranges, can have push button calibration or programmable calibration. The user specifies how frequently the process is monitored and how often the data is transmitted.

Things to consider when using a transmitter: Where will the transmitter be mounted? In what type of environment will it have to function? Does the transmitter need to be programmable? How costly would a measurement error be? This will determine the degree of sophistication your transmitter will require.

There are several different types of mounting set-ups which include:

- Head Mount Transmitters

- Field Mounting Transmitters

- Panel Mount or DIN Rail Mount Transmitters

A “head mount” temperature transmitter is often fitted inside the connection head. The transmitter converts the low-level sensor output to an amplified signal and ensures an accurate signal is made available to the industrial process control system. Thermocouple temperature transmitters convert the small millivolt (mV) output of a thermocouple to a current signal (typically 4-20 mA) output.

Alternatively, a terminal block may be fitted to the connection head and the sensor signal sent to a “DIN rail mounted” temperature transmitter.

The “field mounted temperature transmitter” housings are available in either made of aluminum die cast or of stainless steel with optional indicators and LCD display including device configurability.

HART communication and 4…20 mA analog PV output for individual, difference or average temperature measurement of up to two RTD or TC input sensors. The devices are deliverable with a 1.5”–2” pipe bracket or a wall mounting kit.

Bimetal Thermometers

They are high sensitivity and quality process temperature sensing instruments with exceptional reliability. The options include multi-angle type, side connection type and back connection type. They are made of stainless steel with an accuracy within 1% of the included range. They are made of dissimilar metal making them a flexible wide range of industries. They are used in refineries, pharmaceuticals, food and beverages and much more.

Key Takeaways

- Gas-actuated thermometers give accurate readings because they use gas with a more regular expansion.

- Transmitters convert signals produced by the temperature sensors into a standard instrumentation signal.

- Pressure Gauges work by converting detected process pressure into a mechanical motion.

Continuous research, product development and testing combined with inhouse fabrication facilities assures you of the quality necessary for top performance and long life in your applications. Temp-Pro is a one-call way to help you decide what works best for you. You will get all the services under one roof with comprehensive guidance.