For those unfamiliar, RTDs and thermocouples are sensors that measure heat in Fahrenheit or Kelvin units. Each of these instruments converts temperature readings into electrical conductors. RTDs work on the principle of resistance, which happens uniformly with temperature changes. On the other hand, thermocouples operate on the principle that when two metals are joined together, there is a potential difference at the point of contact that varies with temperature changes. That said, here is a closer look at RTDs and thermocouples and how they are similar and different.

Differences Between RTDs and Thermocouples

When choosing which instrument to use, the general rule is to use an RTD (Resistance Temperature Detector) for temperatures below 850°C and thermocouples above 850°C.

- The sensing element of an RTD is a coiled wire element, while the sensing point of a thermocouple is a twisted or welded joint of thermocouple wire (not wire coiled).

- The extension wire for a thermocouple is a thermocouple-type wire, but the extension wire for an RTD is copper wire.

- Thermocouples must have some reference junction (known temperature or fixed point) at the instrument side. RTDs do not require a reference junction.

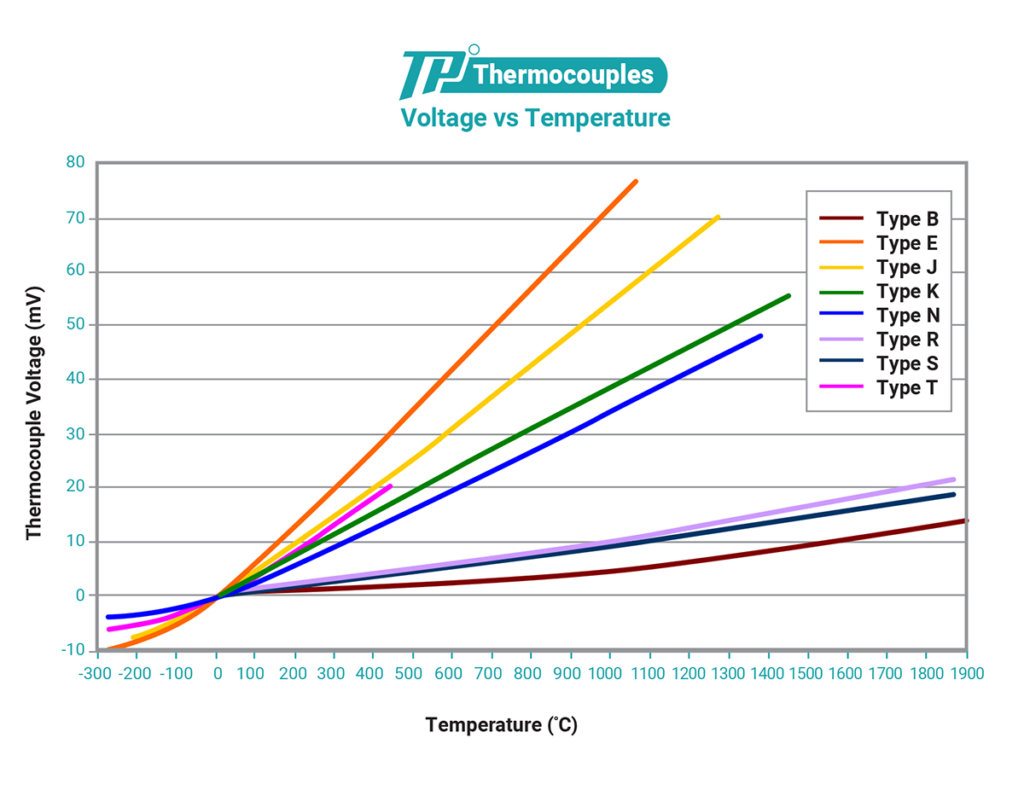

- The instrument to read the signal from the hot point of a THERMOCOUPLE (measuring junction) is usually a VOLTMETER, but the mechanism to read the signal from the hot point (coiled wire) of an RTD is an OHMMETER.

Other Comparable Traits to Consider

Here is a list of other comparable traits to consider:

- Sizing: Thermocouples are usually smaller than RTDs, making them easier to use.

- Range of Operations: Thermocouples offer a more comprehensive range of operation than RTDs (-200 to 2000°C), compared to -200 to 600° C.

- Response Times: Thermocouples offer a response time between 0.1 and 10s which is faster than the response time of RTD sensors.

- Self-Heating Capacity: RTDs can self-heat, while this issue is negligible with thermocouples.

- Sensitivity: Thermocouples are more sensitive than RTD temperature sensors. This is so because these react faster than RTDs with ranges of temperature.

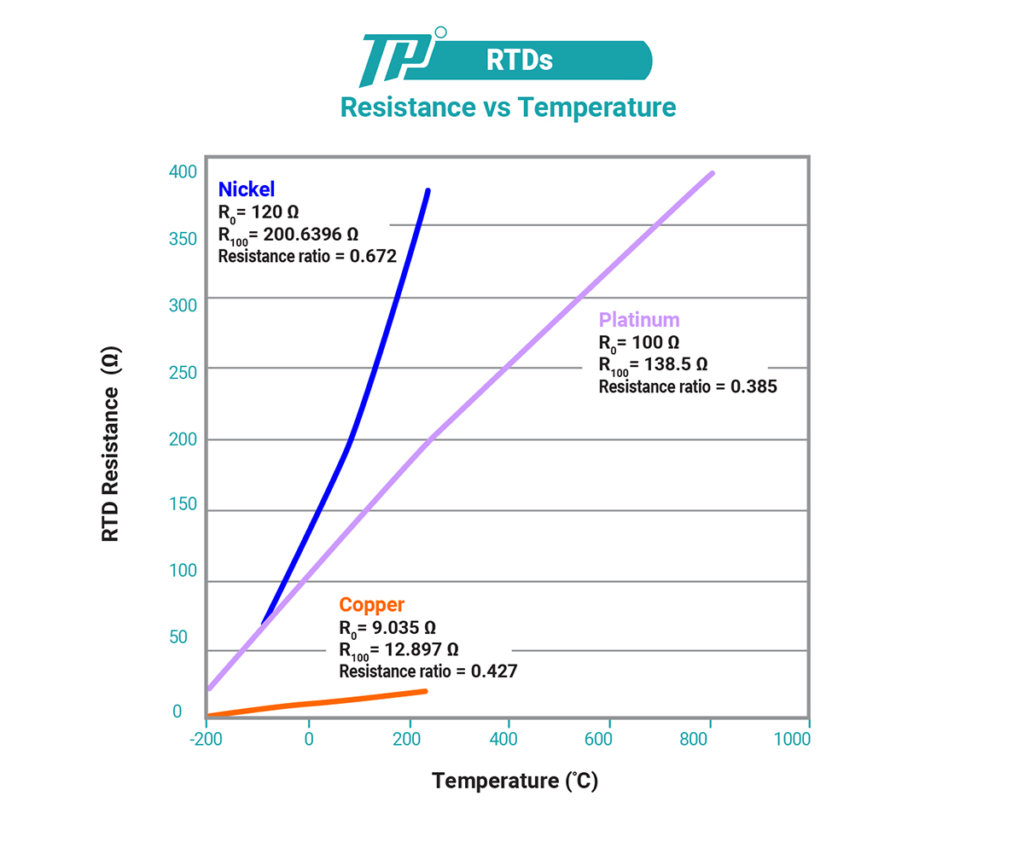

- Linear Graphing: For thermocouples, the graph between resistance and temperature is not linear, while the one of RTDs is.

Uses of RTDs

RTD sensors are so popular because of their accuracy, repeatability, and stability. They generally have higher accuracy than thermocouples.

RTD sensors are so popular because of their accuracy, repeatability, and stability. They generally have higher accuracy than thermocouples.

Every aspect of food production requires constant temperature monitoring – RTD sensors help measure temperature during manufacturing, storage, and shipping.

In HVAC applications, RTD sensors are used for monitoring temperature, fire detection, and climate control. In addition, they help monitor engines, coolants, compressors, fuel tanks, and fire control equipment in aerospace.

Lastly, they are commonly used to monitor all electric motors and machinery for temperature increases, which could damage production.

Uses of Thermocouple Temperature Sensors

Thermocouples are often preferred because of their low cost, high-temperature limits, wide temperature ranges, and durableness. When determining the best option for a thermocouple, there are several factors. These include vital temperature handling capacity, projected chemical exposure, projected mechanical vibrations, and projected abrasion. In addition, thermocouples installed in existing systems must be designed or adjusted for compatibility.

Thermocouples are often preferred because of their low cost, high-temperature limits, wide temperature ranges, and durableness. When determining the best option for a thermocouple, there are several factors. These include vital temperature handling capacity, projected chemical exposure, projected mechanical vibrations, and projected abrasion. In addition, thermocouples installed in existing systems must be designed or adjusted for compatibility.

Thermocouples are used in the following industries:

- Renewable energy

- Mechanical engineering

- Aerospace

- Autoclave

- HVAC

- Power generation

- Cement

- Plastics

- Furnace

- Petrochemical

- oil and gas

- Incineration

- Pharmaceuticals

- Water and water waste

- Commercial food and beverage processing

Either way, most thermocouples have a wide temperature range, good repeatability, and short response time. Other advantages of thermocouples include their diverse temperature measurement capabilities, speed, intelligent probe design, and precision.

Key Takeaways:

- RTDs and thermocouples are two similar products with vastly different advantages and disadvantages.

- RTDs are used for temperatures below 850°C and thermocouples for temperatures above 850°C.

- RTDs are commonly used for temperature monitoring for industrial, oil, gas, refining, power generation, pharmaceutical, food and beverage markets. – Thermocouple sensors are used in industries such as oil and gas, incineration, and more.

If you need RTDs or thermocouple sensors, contact your friends here at Temp-Pro directly.