Industrial settings in the manufacturing world are often demanding, dirty, and hot. Those are also the types of challenges that require the most reliable and accurate turbomachinery and pumps.

Meeting the Demand

Equipment like turbomachinery also excels within specific parameters such as temperatures, speeds, and operating pressures. Optimizing your turbomachinery and pumps to meet specifications within these harsh environments is the key.

Delivering precision and performance requires accurate temperature measurements and obtaining reliable operating pressures. Meeting the demand and getting precision results in even the harshest working conditions relies on not only the type and quality of the temperature sensor but also the placement in the path of the machine.

Industry Strong Durability

To keep turbomachinery equipment running strong, despite adverse environments, requires properly maintaining and measuring machinery and equipment. That is also where reliable and accurate measurement devices play a vital role.

The first step is to ensure that your temperature and pressure measurement devices are working efficiently and accurately. That will not only enable turbomachinery to operate most efficiently, but it will also safeguard against risks and support production.

Extreme heat or pressure can present dangers for people like gas turbine operators and others. These issues are also common culprits for delays, optimizing output, and other production problems.

Industry-Wide Reliability

Safer working conditions, revealing potential concerns, and permitting more accurate monitoring are results of reliable measurements. Behind the scenes, turbomachinery works to provide benefits for many industries. Maintaining and supporting the equipment and machinery that supports our work is not only necessary but smart too.

Turbomachinery is integral to manufacturing operations across commercial, industrial, military, and aerospace applications. Those applications include use in steam turbine processes, compressors, transmissions, generators, electric motors, and more.

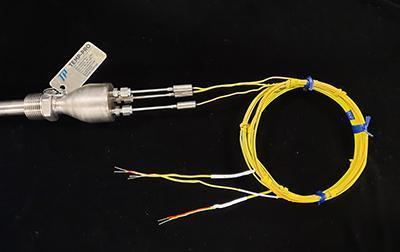

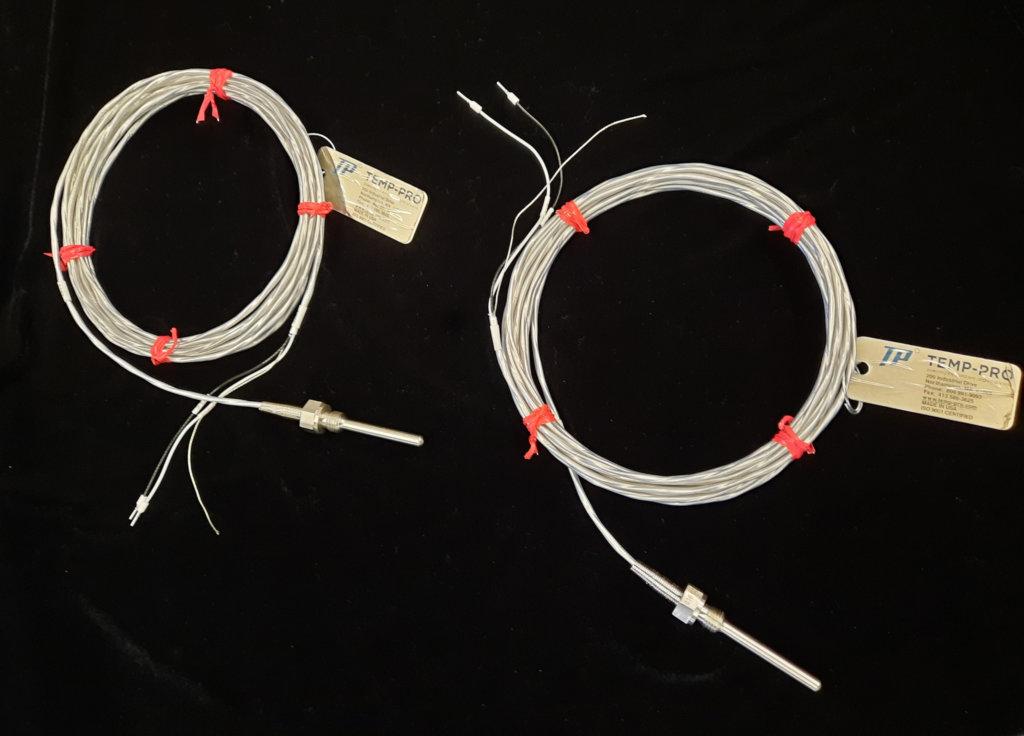

Temp-Pro produces embedment RTDs and Thermocouples found in turbomachinery and rotating equipment. These sensors offer the durability and reliability needed to withstand any manufacturing environment in any industry. Other solutions Temp-Pro designs and develops include:

Embedment RTDs and Thermocouples (Miniature Bearing Temperature Sensors)

Wheel Space, Disc Cavity & Compressor Sensors

Air Inlet or Oil Temperature Sensors

Copper Tip Bearing Temperature Sensors

Exhaust Gas Temperature Sensors

Sensor and Threaded Process Thermowell Assemblies

Sensor and Socket Weld Thermowell Assemblies

Thermocouples (calibrations K, J, T, N or E) and RTD’s with Transmitter

Putting It All Together

Machinery and equipment often face a variety of less-than-ideal working conditions. That includes environments involving oils, dirt, or high temperatures along with components such as stress, vibration and pressure. These situations also demand constant and accurate monitoring to deliver the best possible performance, precision, and production.

From steam turbine operations to gas turbines, many working parts require maintenance and monitoring. Keeping accurate measurements of compressible fluids, temperatures, and operating pressures are all part of the bigger picture. Temp-Pro offers a complete line of OEM replacement and aftermarket equivalent sensors for steam and gas turbines.

Turbomachinery, for example, requires close monitoring of the bearings’ temperature. Seemingly small factors like these directly impact the engine power and performance of any machine relying on these pumps. Turbomachinery and pumps all need to work together to deliver the best results. Temp-Pro produces embedment RTDs and Thermocouples (Miniature Bearing Temperature Sensors) found in turbomachinery and rotating equipment—specifically in bearings, shaft and housing components. That also means ensuring the most reliable and accurate monitors and sensors.

Takeaways

From the outside looking in, it looks like motors, engines, and equipment humming along smoothly. From the inside, however, it looks like a million small tasks that keep it all working together. The performance and precision of those parts also rely on the performance of sensors and monitors.

- Temp-Pro designs and manufactures a complete range of industrial temperature measurement devices for your equipment.

- Embedment RTDs and Thermocouples (Miniature Bearing Temperature Sensors) alert turbine and machine operators of potentially dangerous situations (e.g. temperature thresholds).

- Maintaining and monitoring turbomachinery and pumps is essential to the performance of machinery, motors, and equipment.

Get Optimal Performance from Your Turbomachinery and Pumps

If you want to investigate more about getting the most out of your turbomachinery or learn how Temp-Pro can help optimize performance, contact us today. Temp-Pro can custom design and develop a temperature sensor solution to fit your specific industrial operation to get peak performance under any conditions.