Thermocouples are temperature sensors consisting of two dissimilar metals acting as electric conductors. Temperature measurement is based on a phenomenon where the reference is subtracted from the high temperature of the measuring junction. The measuring end is called the hot junction, while the reference is the cold junction.

Thermocouples are the conventional temperature measuring tool in the manufacturing industry because they are accurate, withstand extreme temperatures, inexpensive and durable.

Types of Thermocouples

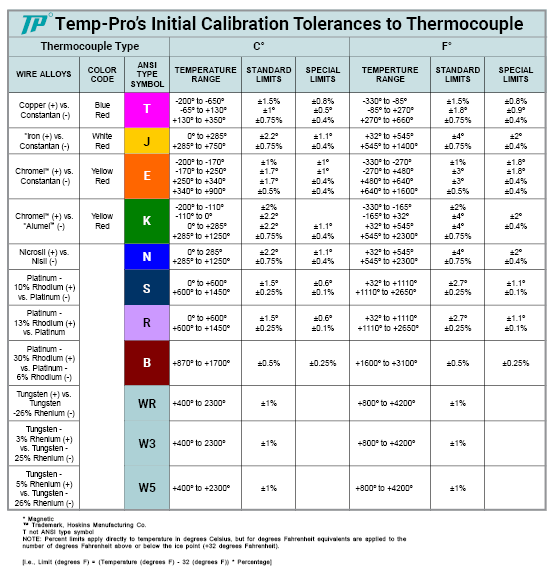

The manufacturing industry is particular with the tools used, and the thermocouple is no different. The thermocouple uses dissimilar metal based on the industry, temperature range and conductor sensitivity. There are eight thermocouple types; B, E, J, K, N, R, S and T.

B-Type Thermocouple

B-type thermocouples combine the Platinum (30% Rhodium) and Platinum (6% Rhodium) alloys. These thermocouples are best suited for high-temperature activities and processes and have temperature ranges of 1370-1700℃ or 2500-3100℉. Cold junctions are not required in B-type thermocouples because they produce the same electrical output at 0°C and 42℃. Their incredible heat resistance makes them perfect for inert and harsh conditions, such as glass production and cement manufacturing.

R-Type Thermocouple

R-type thermocouples made from platinum (10% Rhodium) and Platinum alloys can be used for activities whose working temperatures fall between 870-1450℃ or 1600-2640℉. Despite its accuracy, R-type thermocouples become reactive at temperatures above the thousand-degree Celsius mark and can be easily contaminated. Therefore, their accuracy and stability are better utilized for low-temperature activities like sulfur recovery units. R-Type thermocouples are ideal for high-temperature applications in industries such as glass production & petrochemical processing.

S-Type Thermocouple

Although the S-type performs similarly to the R-type, it is nowhere near as stable. This means that S-types must be protected from metallic and non-metallic vapors. Platinum only became the standard to measure temperature ranges between 630-1064℃ as the freezing points of antimony, silver and gold are not so distinct during this span. S-types are Platinum (10% Rhodium) and Platinum and are commonplace in the medical industry.

E-Type Thermocouple

Chromel and Constantan are the alloy combination in E-type thermocouples, and they have a characteristic temperature range of 0-870℃ or 32-1600℉). E-types’ high output, fast response times and non-magnetism make them ideal for use in cryogenics, aviation and flow chambers. E-types are rated over the K and J-types at temperatures 1000℉ and lower because of their stability, accuracy and stronger signal.

J-Type Thermocouple

The temperature range of J-types is 0-760℃ or 32-1400℉, and they can tolerate heat for up to 1000℃ (2552℉). They degrade rapidly in oxidizing atmospheres above 550°C. Their maximum continuous operating temperature is around 750°C though they can withstand short duration excursions to 1000°C. They are made from Iron and Constantan and are the least expensive thermocouple option in manufacturing. However, they are susceptible to rust, and using them below ambient temperatures shortens their lifespan further.

They are generally not used below ambient temperature due to condensation forming on the wires leading to rusting of the iron. It has a smaller temperature range and a shorter lifespan at higher temperatures than the Type K. Best suited for the plastics industry & general industrial offering cost-effectiveness and reliability.

N-Type Thermocouple

N-types spot an alloy combo of Nicrosil and Nisil. They are more consistent when measuring between 300℃ and 500℃ (572 to 932℉) but are less stable because the thermocouple wires oxidize quickly. With an accuracy and price point that rivals the K-type, the N-type is considered a better alternative to the R and S-types. Perfect for the aerospace and power generation industries, offering superior performance and stability in high-temperature environments especially where thermocouple longevity and resistance to oxidation are required.

K-Type Thermocouple

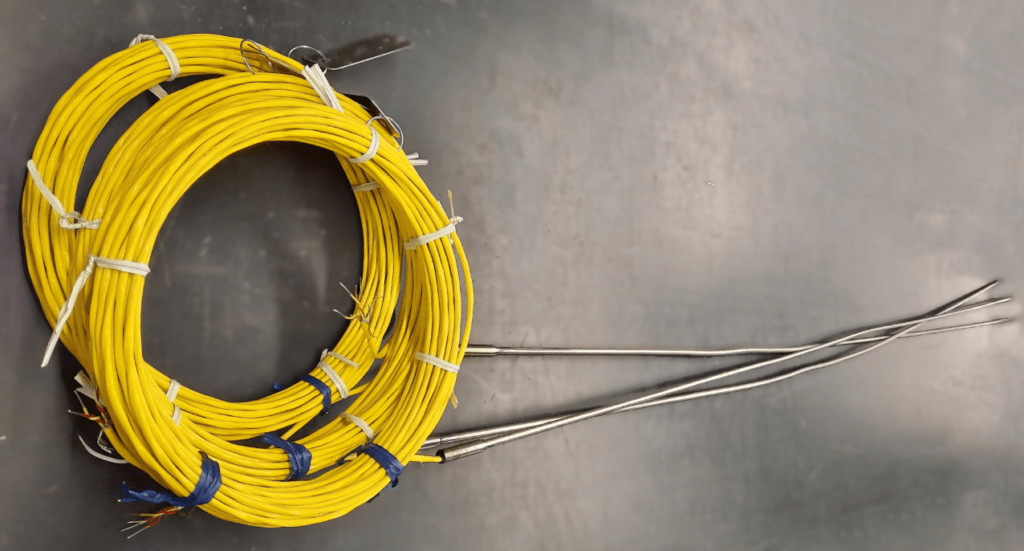

K-type thermocouples are formed by the Chromel and Alumel combination of metals, with preferred working conditions between 0-1260℃ or 32-2300℉. Type K thermocouples are the most widely used thermocouples in the Oil & Gas, and refining industries due to their wide range and low cost. The type K is also commonly used in nuclear applications because of its relative radiation hardness.

While K-types may be accurate, they need recalibration when used for temperatures around and above 750℃. Noble metal types are an alternative if corrosive resistance is the primary concern.

They are occasionally referred to as Chromel-Alumel thermocouples. The type K is the most common type of thermocouple. It’s inexpensive, accurate, reliable, and has a wide temperature range.

The most versatile and widely used thermocouple, ideal for the oil & gas and food processing industries providing both durability and accuracy across various applications.

T-Type Thermocouple

T-type thermocouples are very stable and work best between -59℃ to 370℃ or -75 to +700℉, making them the best bet for use in low-temp lab processes like cryogenics and ultra-low freezers. The T-type is consistent with measurements between -200℃ and 200℃ and is decomposition-resistant. They are made from Copper and Constantan.

Choosing the Right Thermocouple

Thermocouples are capable of measuring different ranges and might be more accurate within a certain range. It is important to make sure that your application use is within the range before purchasing. The temperature range of the temperature sensor is provided on the datasheet.

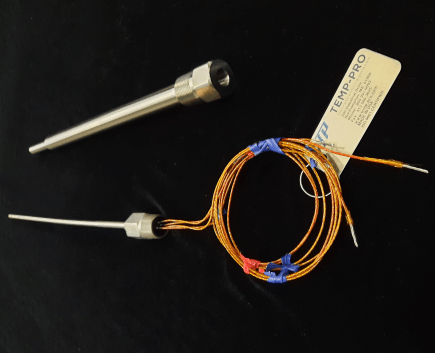

Selecting the thermocouple type is not the only consideration. Factors such as sheath materials, time at temperature and degree of accuracy are also critical. Ensuring sufficient immersion length, the sensor should extend into the process a minimum length equal to one-third the inside diameter of the pipe, with the optimal location at the center of the pipe diameter. Design considerations include how the temperature sensor will be connected to the application and how the temperature is going to be measured as these will both affect the choice.

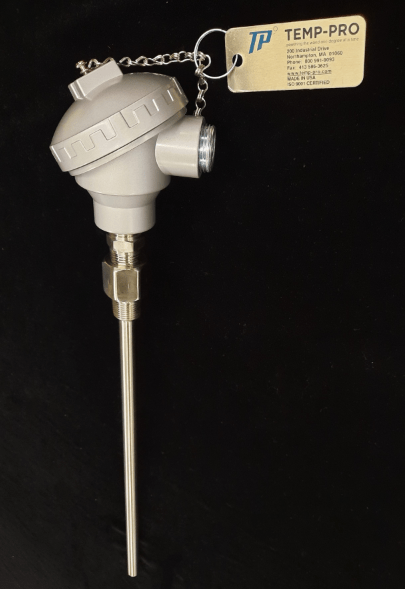

Still unsure? That’s where Temp-Pro can help. Our application assistance services begin with an inquiry to determine the product, its application and the solution it can deliver, triggering additional inquiries to evaluate options and devise a plan of action to meet your needs.

We also collaborate with our sensor engineering expertise to support a variety of innovative or “reverse” engineering applications related to temperature sensors. Temp-Pro has always been in the forefront of industrial temperature device design and manufacturing, listening to our customers and industry leaders to develop the most effective solutions for their everyday challenges.

Contact Temp-Pro for Your Thermocouple Needs

Choosing the most suitable higher temperatures metal thermocouples requires considering factors like accuracy within temperature ranges, stability, base metal, size and sensitivity. At Temp-Pro, we’re not just committed to delivering high-quality temperature sensors & electrical enclosures; we’re ISO 9001:2015 certified, underscoring our consistent dedication to excellence and customer satisfaction across all our products and services. Temp-Pro is the foremost manufacturer of aftermarket and custom temperature sensors to match clients’ needs using our in-house reverse engineering methods. Our expert engineers can also assist you in incorporating our devices into your gas turbine system. Send us a message or call us today at 800-991-9093 to improve your industrial process.