Key Takeaways:

Critical Role of Temperature Sensors in Aerospace Safety: Temperature sensors are crucial in the aerospace industry, ensuring the safe operation of aircraft control systems by monitoring & reporting critical temperature changes in real-time.

Diverse Applications and Sensor Types: The aerospace industry benefits from a wide variety of temperature sensors, including RTDs, thermocouples, and flow sensors, each suited for specific environments and tasks within aircrafts.

Temp-Pro’s Expertise and Custom Solutions: Leveraging their ISO 9001:2015 certification, Temp-Pro offers tailored temperature sensing solutions that meet the exacting standards and unique needs of the aerospace industry, enhancing safety and operational efficiency.

Pressure sensors play an integral role in the safe operation of aerospace vehicles. Learn how the aerospace industry benefits from temperature sensors.

The global aircraft sensors market is worth $3.5 billion. As an aerospace industry manufacturer, you know the value of a sensor that works—and how lethal a dysfunctional sensor can be.

Read on to discover how temperature sensors get you the fast, reliable data pilots need—at a price manufacturers can’t afford to pass up.

What Do Aerospace Industry Leaders Need From Sensors?

Sensors are critical to the task of piloting and operating an aircraft. Sensors record changes in temperature, pressure, and the motion of cooling fluid.

The sensors then report these changes to pilots or onboard computer systems. The reports convey critical information about all aspects of an aircraft—all of which are necessary to take off, land, or maneuver safely.

Different types of sensors are better suited to different environments and monitoring tasks within the aircraft. Leaders need sensors that are reliable, durable, and well-suited to the task at hand.

Sensor Types and Functions

Spacecraft and aviation machinery require durable, precise sensors to get accurate measurements in real-time. Engineers have developed three mechanisms sensors can use to input information. This results in three primary, functional sensor designs.

Pressure Sensors

Pressure sensors convert changes in fluid pressure into an electrical signal. The pressure sensor includes a component in contact with the fluid. That’s the diaphragm, bellows, or bourdon tube.

That component physically responds to changes in the fluid’s pressure. Then, the sensor’s transducer converts the kinetic energy of the contact component’s motion to electricity, to send the signal.

The transducer quantifies the change in pressure. This enables precise communication about the pressure change.

This makes pressure sensors useful tools to monitor:

- Hydraulic systems

- Brake fluid systems

- Environmental control systems

- Engines

Temperature Sensors

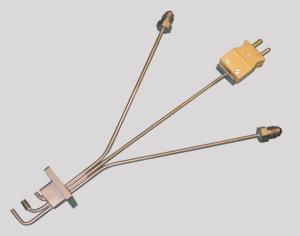

Temperature sensors may be RTDs, thermistors, or thermocouples. Thermocouples are most often used in aerospace applications.

A temperature sensor measures the degree of heat in fuel, hydraulic oils, and coolants. The two most common temperature sensors are RTD’s and thermocouples.

RTD elements most commonly used are platinum either wire wound or thin film. RTD’s are highly accurate, thin film typically used for air temperature

Thermocouples respond to information quickly, and they can withstand extreme high-heat environments This makes thermocouples well-suited to the task of alerting the pilot or system if the engine is at risk of overheating.

Flow Sensors

Flow sensors read the flow of hydraulic oil and coolant fluid. They respond to the direction and velocity of the fluid’s flow. This lets the sensor detect:

- Fuel transfer

- Air bleed

- Leaks

Engineers typically build flow sensors from a primary element and a DP flow transmitter.

Temperature Sensors in the Aerospace Industry: Key Benefits

Temperature sensors offer several benefits in aerospace applications. Benefits of temperature sensors include:

- Reliable information in extreme environments

- Real-time information

- Fast response due to low thermal mass

- Enable precision cooling

- Precise direct-immersion readings with thermocouple/RTD combination

- Vibration resistance

- Fiber-optic option reliable in high-voltage, EMI environments

Temperature sensors can be widely dispersed on an aircraft. This enables both accurate temperature information and precise location information.

Defeating Aerospace Industry Challenges: Thermocouple Temperature Sensors

Aviation and spaceflight are complex tasks. No matter which craft you use, there are challenges inherent to engineering methods of receiving and using accurate, necessary data. Harsh environments and high temperatures can destabilize sensors. High-pressure situations can disrupt signals or cause component malfunctions.

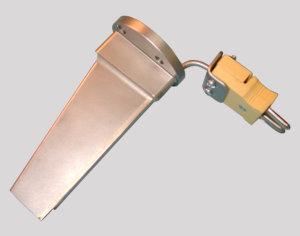

Temp-Pro develops sensors that rise to these challenges. Our temperature sensors come with protection tubes, to enhance durability in industrial environments.

Custom, Resilient Temperature Sensors

What’s the best possible sensor for your craft?

At Temp-Pro, we trust clients to know their equipment best. All sensors are backed by an ISO 9001:2015 certification, and specifically tailored to meet the rigorous demands of the Aerospace industry in the design and manufacturing of temperature sensors. That’s why we manufacture temperature sensors to our client’s specifications. Our sensors can fit and function in non-standard environments. All Temp-Pro sensors are easy to assemble and place for a range of aerospace applications.

If you need sensors for your aerospace design, contact us. Our experts are ready to tackle any of your problems.