In 2020, biomass provided 4.9 percent of primary energy consumption in the United States. Biomass is a renewable organic material that comes from plants and animals.

Biomass is burned for heat or turned into renewable liquid or gas. Burning is the most common method for changing biomass into usable energy.

A biomass project needs precise temperature readings. Otherwise, it could be in danger of over or under-heating the processed materials. This danger could lead to severe financial losses or a total project shutdown.

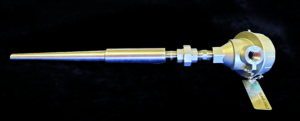

Temp-Pro’s temperature sensors have a unique design that gives power plants perfect exhaust gas temperature readings allowing power plants to make the necessary changes to stop potential disasters.

Prevent Over or Under Heating Of Materials

Biomass is a renewable energy source made from different sources. Its primary energy sources include wood, wood processing waste, crops, and agricultural waste.

Biomass power plants also use paper, cotton, and food found in municipal garbage. Animal manure and human sewage are also used.

Biomass can be burned for heat, such as wood for a fire. Or biomass facilities can change it into renewable liquid and gas fuels. The resulting gas or oil replaces fossil fuels.

Biomass can go through different heating processes to make biofuel. Facilities use thermochemical methods like pyrolysis, gasification, and burning.

Biomass burns in a boiler to make high-pressure steam. The steam is then released and causes a series of turbine blades to rotate, which drives a generator.

Gasification is a process where power plants change biomass material into gas. Biomass converts at high temperatures of over 700 degrees celsius.

The method doesn’t use combustion and uses a controlled amount of oxygen. Biomass changes into carbon monoxide, hydrogen, and carbon dioxide.

The carbon monoxide reacts with water to form more carbon dioxide and hydrogen. Special membranes separate the hydrogen from the gas stream.

Pyrolysis is like gasification. But the method uses lower temperatures and no oxygen to make a bio-oil. The bio-oil is then used in place of fuel oil or diesel to create electricity.

Each process must reach the ideal temperatures to change biomass into biofuel. With Temp-Pro’s temperature sensors, you can track the temperature of the gases. Regulating these temperatures makes sure that the biomass reaches the temperature it needs.

Temperature Sensors Can Protect Your Biomass Pile

Power generating plants store their biomass fuels in large piles or silos. Biomass fuels are known to heat up spontaneously or burst into flames. So keeping biomass fuels like this increases the risk of fire hazards.

Biomass facilities need a way to measure the temperature of their storage piles. Luckily, Temp-Pro has a solution.

A sensor can watch a biomass pile to spot fire hazards. Facilities can get real-time feedback on their store pile. So if temperatures rise, they can act to prevent disaster.

Help Power Plants Save Money

Biomass needs to go through proper treatment. This treatment stops biodegradation and loss of heating value. But this also increases the production cost and the equipment’s investment.

The biomass pretreatment stage is vital for a successful production. Especially for biofuel production in the downstream processing units. The treatment process takes place in large pressurized thermal reactors.

The biomass enters the reactors at a constant speed. This speed is to make sure there is continuous output.

This method presents an irregular temperature distribution inside the reactor. Temp-Pro’s sensors can help maintain an ideal temperature model during this process.

Biomass has a low energy density. It needs more feedstocks to make the same amount of energy as traditional fuels.

High moisture content is a problem for biomass plants. It causes degradation, mold growth, and losses in organic contents during storage. These challenges can reduce the yield of fuel produced.

Densification is a process facilities use to overcome low density and moisture problems. This process compresses biomass.

The compression increases its density and makes them into uniform shapes and sizes. Densification lowers costs for the facility.

The compressing process has three main stages. These stages are drying the bio-feedstock, grinding or size reduction, and thermo-mechanical compaction. It is vital to control the air-to-fuel ratio during transition states.

Poor control can cause the process to move out of the ideal combustion interval. Poor control can also cause heat losses and high emissions.

The temperature of the press helps to make denser pellets. Pressure gauges will also be beneficial for densification.

Biomass Projects and Temp-Pro’s Temperature Sensors: A Perfect Match

Temp-Pro is a leading manufacturer of industrial temperature sensing devices. They currently supply temperature measurement products to two biomass power plants in Georgia.

Temp-Pro has installed its devices in various equipment. Such as boilers, turbines, cooling towers, ash systems, wood yards, and dryer systems.

Temp-Pro installed the following devices for the Georgia Renewable Power projects:

- Pressure gauges

- Bimetallic/gas thermometers

- Thermocouples socket weld

- Thermocouples flanged

- Thermocouples for grate

- Thermocouples close-end tube

- Thermocouples metal temperature

Temp-Pro’s temperature sensors are a perfect match for the renewable energy industry. With the sensors, customers have better control of heating conditions. And they can measure the extreme energy conditions in their energy-generating equipment.

Temperature sensors provide several benefits to biomass facilities. Without these, you can’t effectively produce energy. And your facility might be a fire hazard.

Find the Best Biomass Temperature Sensors Today

Power plants need a high degree of accuracy to measure and control flue gas temperature. Inaccurate temperature readings can lead to potential fire hazards.

Get the best temperature sensors on the market. Contact us and let us help you find the best temperature sensor for your project.